19 3月 Ceramic Fiber Blanket Suppliers

Ceramic Fiber Blanket Suppliers from China Factory. Please contact our email sales@adtechamm.com

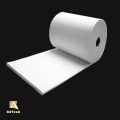

Ceramic Fiber Blanket Characteric

Excellent tensile strength

Low thermal conductivity

Low heat storage

Corrosion resistance

Thermal stablity

Resiliency

High heat reflectance

Thermal shock resistance

Ceramic Fiber Blanket Suppliers

Ceramic Fiber Blanket Application range

1, Industrial furnace building, heating equipment, and high-temperature pipe wall lining materials.

2, Electric boilers, gas turbines and nuclear power insulation.

3, High-temperature chemical reaction industrial equipment and heating equipment lining the wall.

4, Fire safety in high-rise buildings and insulation.

5, Kiln oven door, roof insulation.

6, High-temperature filter material

Ceramic Fiber Blanket Suppliers said that ceramic fiber blanket, also known as aluminum silicate fiber blanket.

Because one of its main components is alumina, and alumina is the main component of porcelain, it is called ceramic fiber blanket.

Ceramic fiber blankets are mainly divided into ceramic fiber blown blankets and ceramic fiber spin blankets. Ceramic fiber spin blankets are superior to ceramic fiber blow blankets in terms of thermal insulation due to the long fiber filaments and small thermal conductivity.

Ceramic Fiber Blanket Composition

| Composition | 1260

Ceramic Fiber Blanket |

1400

Ceramic Fiber Blanket |

1500

Ceramic Fiber Blanket |

1600

Ceramic Fiber Blanket |

| Temperature(°C) | 1260 | 1420 | 1500 | 1600 |

| Melting point( °C) | 1760 | 1800 | 1900 | 2000 |

| Colour | White | White | Blue and green | White |

| Average Fiber Diameter (um) | 2.6 | 2.8 | 2.65 | 3.1 |

| Fiber Length(mm) | ~250 | ~250 | ~150 | ~400 |

| Weight(Kg/m) | 2600 | 2800 | 2650 | 3100 |

| Shot Content (%)

( > 212um) |

12 | 12 | ||

| Kcal/mh°C(W/mK) ,ASTM C201, 190kg/m | ||||

| Average 400°C | 0.08 | 0.08 | ||

| Average 600°C | 0.12 | 0.12 | ||

| Average 800°C | 0.16 | 0.16 | ||

| Average 1000°C | 0.23 | |||

| Composition | ||||

| Al2O3 | 47.1 | 35.0 | 40.0 | 72 |

| SiO2 | 52.3 | 46.7 | 58.1 | 28 |

| ZrO2 | 17.0 | |||

| Cr2O3 | 1.8 | |||

Sorry, the comment form is closed at this time.