24 4月 Ceramic Candle Filter

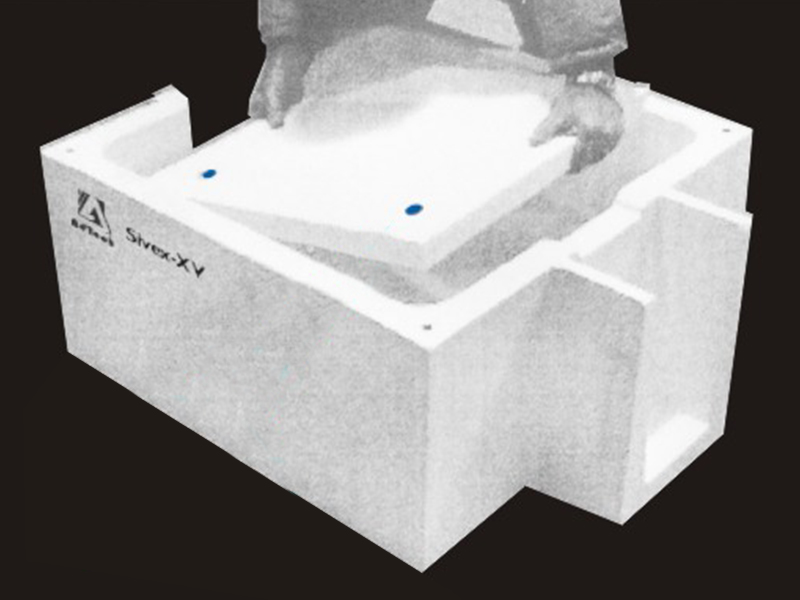

Ceramic Candle Filter

DTECH keeps focusing on the manufacture of the metallurgical material, including Ceramic Candle Filter.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM

Metals and metallic products have a special connotation with human civilization.

It is considered to be one of the primitive material that human have mastered to use.

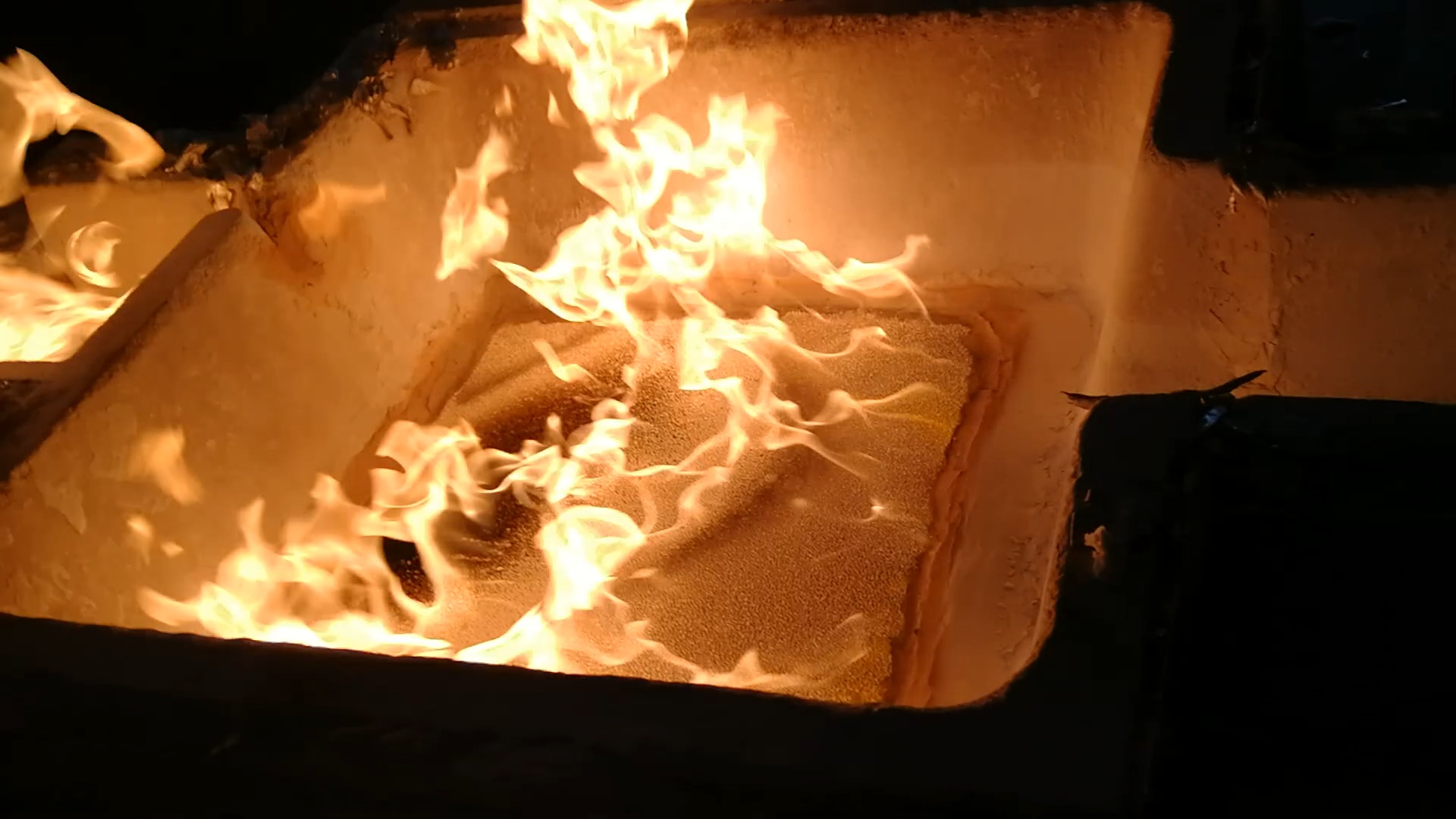

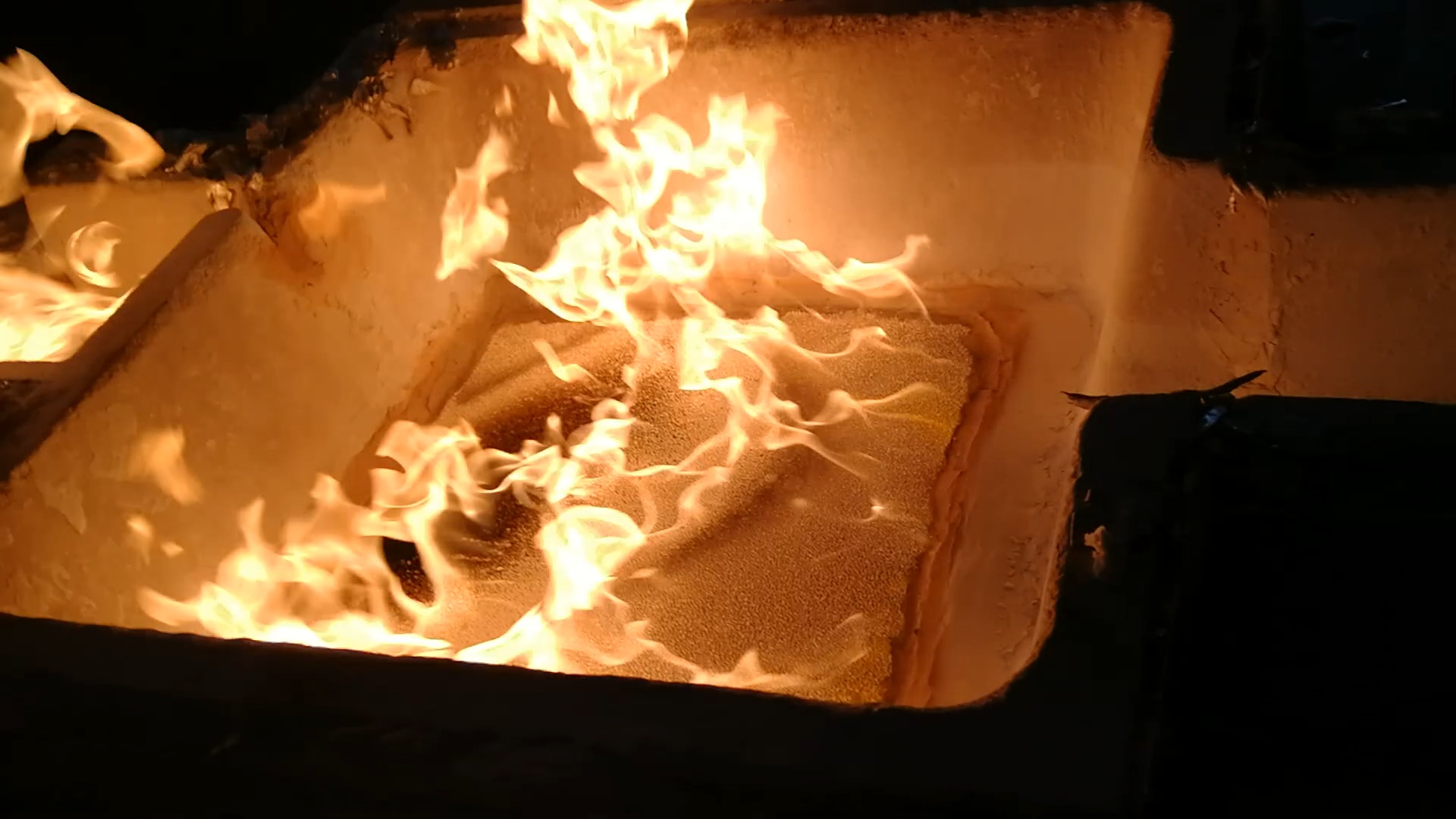

However, all metals are not very stable in its rawest form. This form of metals may not have the optimum metallic properties and therefore it requires purification. Purification process of molten metal require ceramic ceramic foam filter, which ensure that all the impurities has been removed from the metallic solution.

Once this process is achieve, metal is ready to be used in different types of applications through different processes.

Compressed strength The amount of raw material used during the purification process is very high, as doing this process in small quantities is not a cost effective solution.

Therefore, heavy amount of metallic solution is poured over these filters and therefore it must have a high compressed strength to undergo the operation undamaged.

Natural melting points of various metallic elements are very high. The range of melting point of metals may vary but generally is around few hundred to more than thousand degrees Celsius.

It is therefore very necessary that Asian Foundry Filters must have certain properties. Here are some useful properties

Porosity It is the percentage of the pore space in the Asian Foundry Filters.

This property is very important in operations as a filter with much larger or smaller porosity can hamper the process. Therefore, it is recommended that porosity must be ideal in terms of the types of molten metal used.

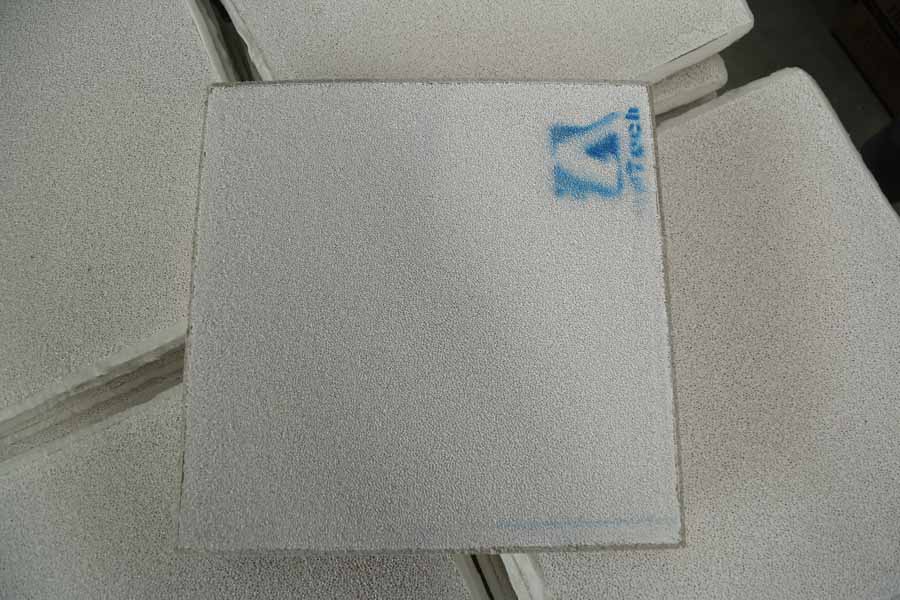

Ceramic Candle Filter Specifications

7*7in 9*9in 12*2in 15*15in 17*17in 20*20in 23*23in 26*26in, or customized according to customer requirement.

Pore size (mesh): 25 30 35 40 45 50 55 60.

Ceramic Candle Filter Performance

Filter-PZr filter is produced from high temperature sintering ZrO2 molten material, usable at high temperature, high strength, erosion resistance, minimal volume change, can effectively filter out micron-scale inclusions in molten aluminum, mainly used in aviation, transportation and other aluminum alloy precision casting.

Aperture microgram: (Aperture microgram)

Ceramic Candle Filter Features

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

Sorry, the comment form is closed at this time.