22 4月 Degassing Machine Coimbatore

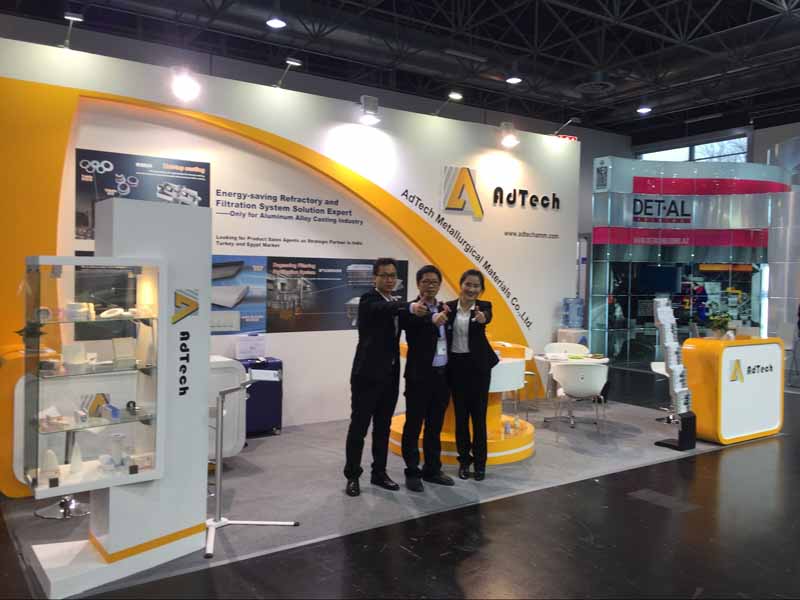

Degassing Machine Coimbatore ADTECH keeps focusing on the manufacture of the metallurgical material. ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material. 1.Ceramic Foam Filter 2.Degassing Unit 3.Filter Box 4.Hot-top casting series 5.Roll casting nozzle 6.Flux series 7.Other Metallurgical Material SALES@ADTECHAMM.COM Degassing Machine Coimbatore Working Principle(www.adtechamm.com) The...