21 6月 Aluminum Ingot Continuous Casting Filter Foundry

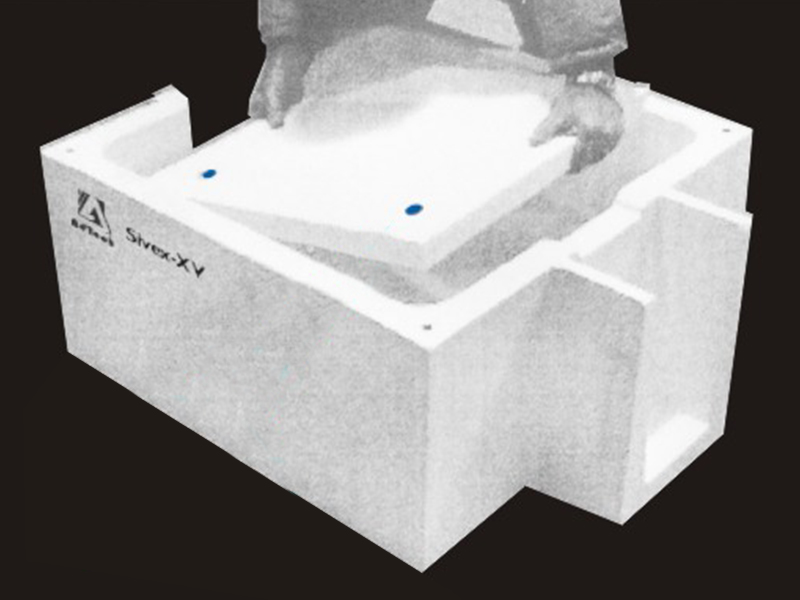

Aluminum Ingot Continuous Casting Filter Foundry

Filter Foundry Application

For the filtration of molten aluminum and non ferrous alloy.

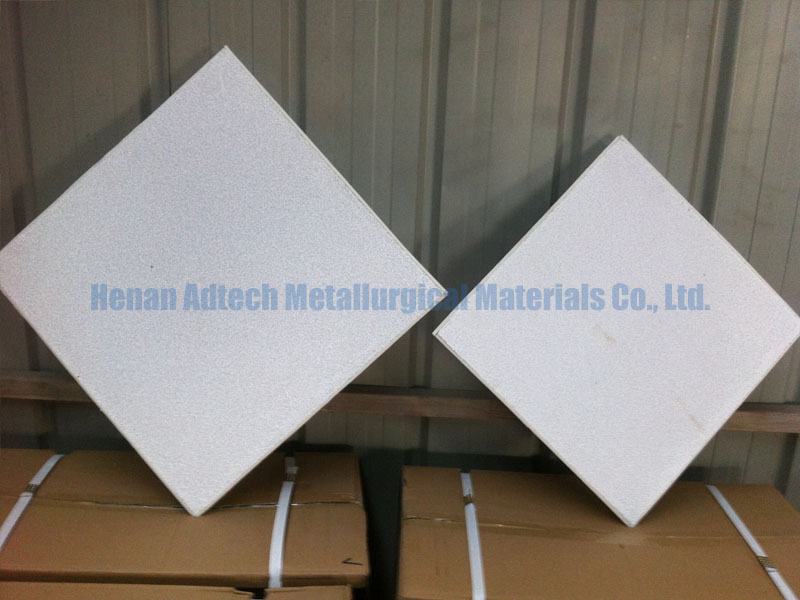

Alumina Ceramic Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses .With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

Continuous Casting Filter Foundry provide a cost effective and proven method to remove inclusions from aluminum melts. The exact removal efficiencies can vary greatly depending on application conditions. Typically, efficiency increases as filter cell size and the velocity of the metal in the filter decrease.

Choosing the right size of a Ceramic foam Filter

The following two basic rules are valid for ceramic foam filter in aluminum casting applications: Filter capacity: approx. 14.2-28.4 lb/in2 Casting speed: approx. 0.7- 1.42 lb/in2*s

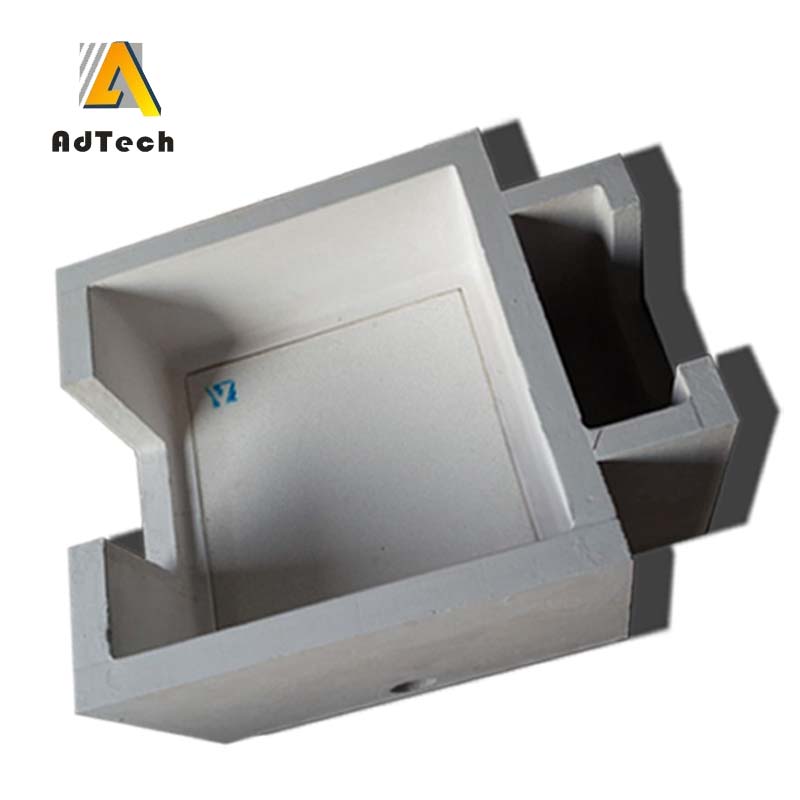

It is recommended designing the runner-gating system as shown in Picture 1:

While adding the filter print to the mould plate, the filter seat has to be sized correctly to prevent filter breakage while casting. It is recommended to have a filter size of approx.. 1/5” for filters up to 3×2”, filters up to 4×4” need 1/3“ of filter seat while filters larger than 4×4” need approx. ?” filter seat. Filters up to 4×4” can be positioned vertically or horizontally inside of the mould/runner, larger filters should be positioned horizontally only. It is not recommended to position the filter at the bottom of the downsprue, as the risk of filter breakage is significantly increased. When ceramic foam filters are used, it is recommended to use a “pressure-free” casting system, to prevent re-oxidation of the molten Aluminum while casting.

Please note: All the information above should be considered as a guideline, not as guaranteed.

Sorry, the comment form is closed at this time.