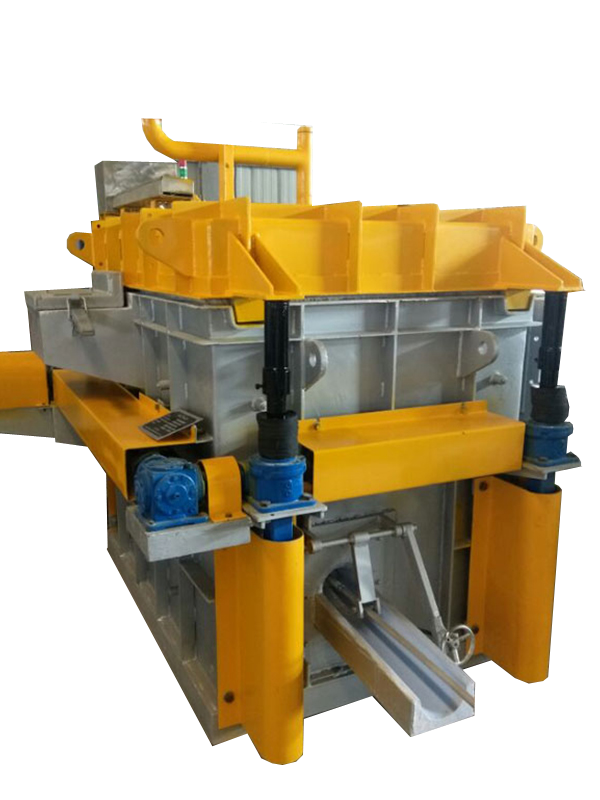

14 5月 Aluminium Foundry Hydrogen Degassing Unit

Hydrogen Degassing Unit

The hydrogen content of aluminum melt has a decisive influence on the properties of aluminum and aluminum alloys. Therefore, Hydrogen Degassing has become one of the necessary means to control the quality of the aluminum processing industry. The Hydrogen Degassing method and Hydrogen Degassing equipment for aluminum melts have developed quite rapidly, and there are many Hydrogen Degassing Unit developed.

At present, the most complete, reliable and repeatable aluminum melt liquid Hydrogen Degassing technology is Adtech Hydrogen Degassing Unit.

Multi-rotor online aluminum fluid Hydrogen Degassing equipment is a product used to improve the quality of aluminum liquid and improve the mechanical properties of castings.

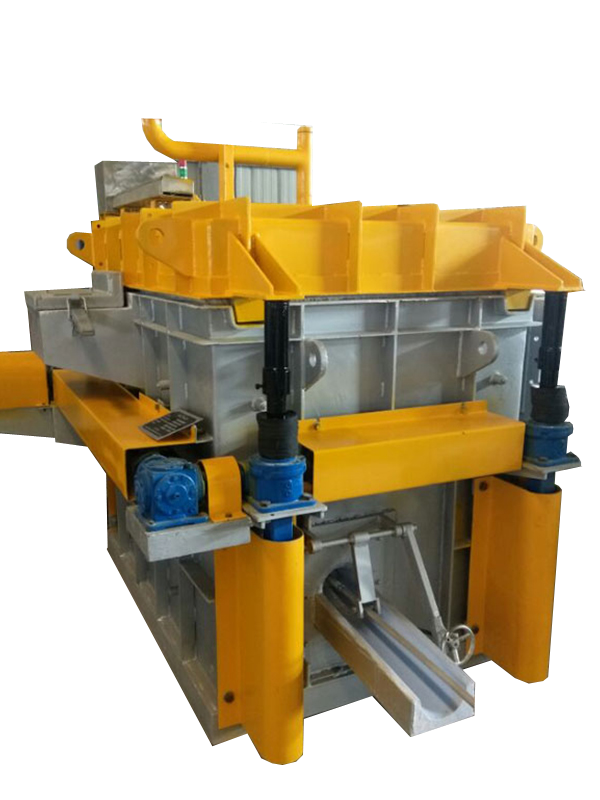

Principle of Hydrogen Degassing: The rotating inert gas is injected into the aluminum liquid through the rotating graphite rod and rotor. The rotor breaks the inert gas entering the aluminum liquid into small bubbles and evenly disperses into the aluminum liquid. These inert gas small bubbles Hydrogen and other non-metallic impurities trapped in the aluminum liquid are floated together with the small bubbles of the inert gas to the surface of the aluminum liquid to achieve the effect of removing hydrogen.

Hydrogen Degassing Unit Technical Parameters

1. Number of rotors: 1 to 3 rotors are optional, and multi-stage degassing efficiency is higher.

2. Degassing object: hydrogen in the flowing aluminum liquid in the launder or degassing tank.

3, the maximum processing capacity of aluminum liquid: each rotor can handle 5t / h aluminum liquid.

4, electromechanical characteristics: electric lifting and rotating, easy equipment maintenance and graphite rotor replacement. The electric chain up and down lifting stroke is ≤600mm; the electric slewing bearing gear transmission rotation angle is 180. The motor power is 2~7KW. Both the power interface and the pneumatic interface on the device use quick release connectors. The inlet and outlet of the flow cell are embedded with a partition plate, and the graphite baffle of the upper cover forms separate degassing chambers.

5, degassing speed: 0 ~ 600 rev / min, digital display speed is adjustable, every 3 rotors can be independently controlled.

6. Degassing medium: industrial dry nitrogen or argon with a purity of 99.996% or more, each rotor gas flow is adjustable from 0.25 to 2.5 Nm3/h; gas input pressure is 0.4 to 0.6 MPa (automatic alarm prompt replacement when less than 0.2 MPa) Gas source);

7. Degassing effect: Calculated according to each rotor, when the inlet flow rate is not more than 5t/h and the inlet hydrogen content is not more than 0.35ml/100g, the 700-730°C aluminum liquid can reduce the hydrogen content to below 0.19ml/100g. When the imported hydrogen content is greater than 0.35 ml/100 g, the degassing efficiency is not less than 45%.

8. Automatically alarm when a fault occurs, and the indicator light flashes to remind the operator.

9. The maximum temperature of the outer wall of the furnace shell is ≤75°C.

Sorry, the comment form is closed at this time.