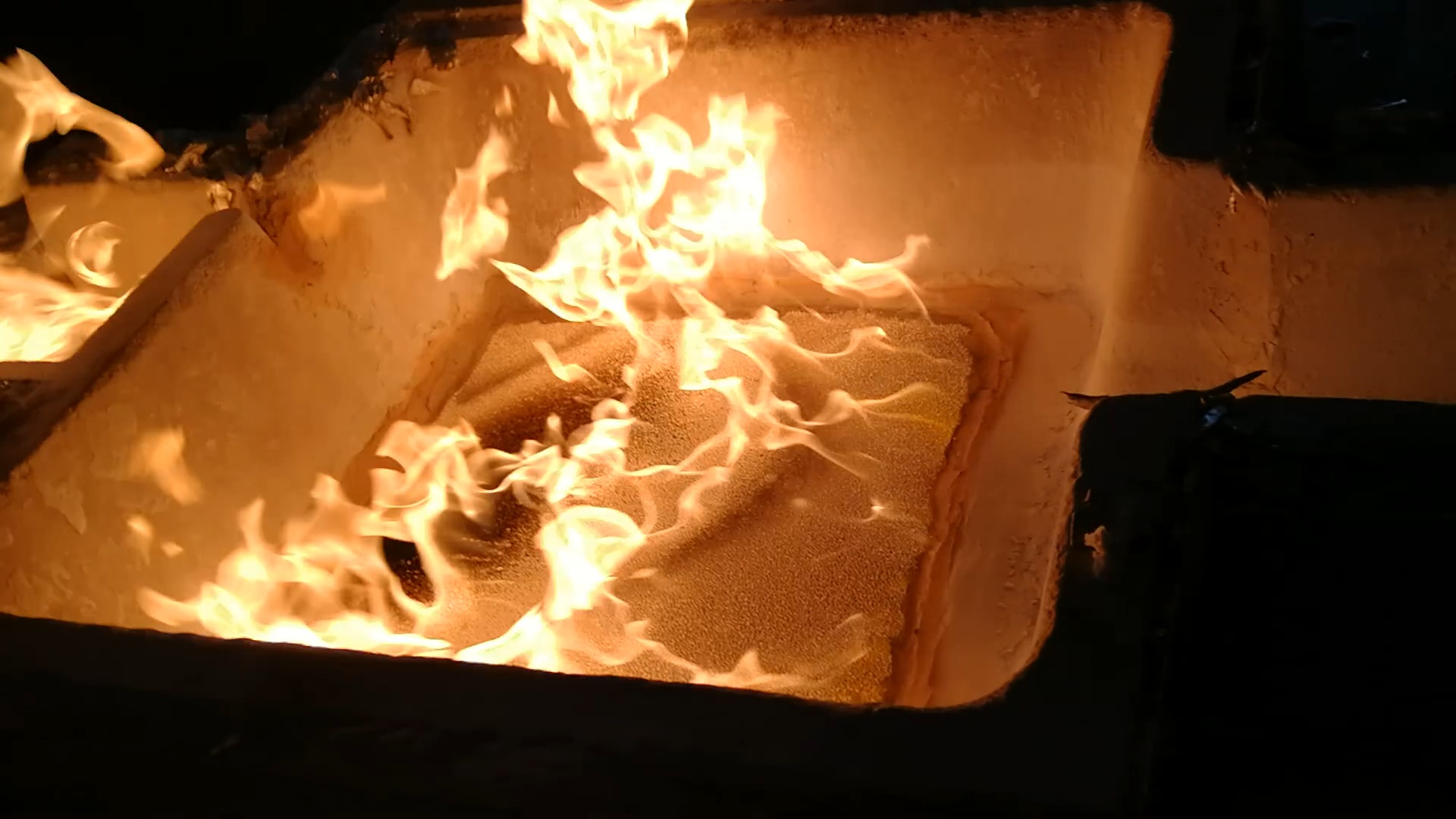

17 6月 ALuminium Ceramic Fiber Castertip

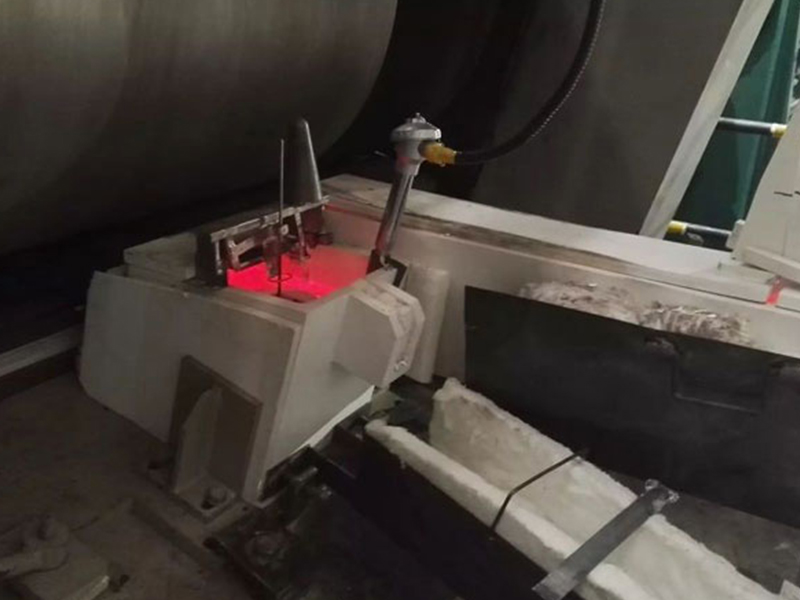

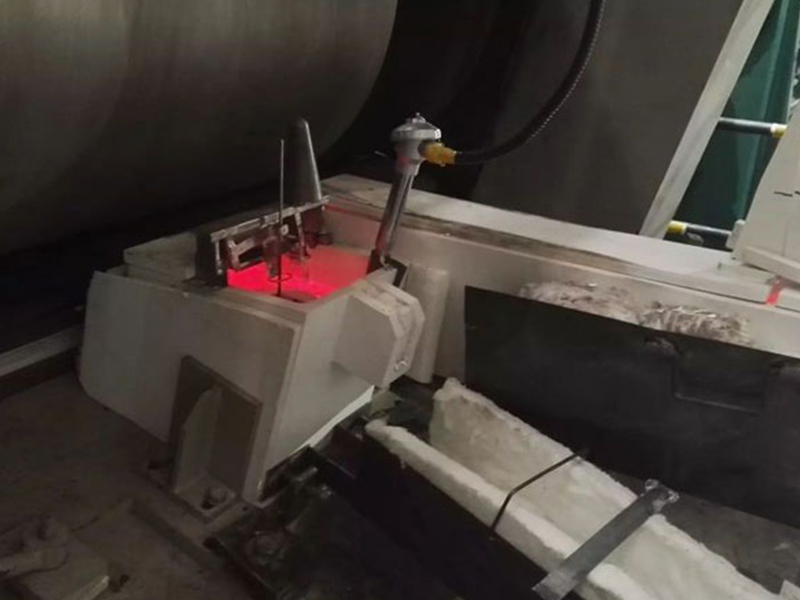

ALuminium Ceramic Fiber Castertip is essential in the aluminum alloy casting and rolling process.

The adjustment of the opening of the casting nozzle and the adjustment of the plate shape are important for the production of aluminum products. Therefore, they have a great influence on the quality of the product.

In the related art, the casting nozzle includes an upper splint located at the upper part of the casting nozzle, and a lower splint located at the lower part of the casting nozzle, and the upper splint and the lower splint clamp the casting nozzle through a threaded connection, which must be performed reasonably.

In the production of aluminum alloy casting and rolling strip, the aluminum alloy is cast and rolled into billets using a casting and rolling machine.

ALuminium Ceramic Fiber Castertip is an important component. The aluminum alloy is fed into the channel of the roll gap from the front box of the casting and rolling mill. How the aluminum alloy melt is split in the nozzle will directly affect the quality and output of the strip. Therefore, the internal structure of the nozzle is stable. The casting and rolling process and improving product quality play a key role.

The structure of the casting nozzle of the casting and rolling machine should meet the reasonable flow line (laminar flow) and no dead zone (no turbulence) when the aluminum alloy melt passes through the front box; the melt is evenly distributed over the entire length of the roll gap.

The temperature of the melt flowing into the roll gap should be uniform.

According to the boundary layer theory of fluid mechanics, after the melt enters the nozzle, it flows toward the outlet of the nozzle with the least resistance under the static pressure of the liquid level in the front tank.

The flow rate in the central area of the nozzle away from the boundary is greater than the boundary area. In order to keep the liquid flow at the outlet basically stable and the flow rate is consistent, to maintain a normal casting and rolling balance, the appropriate flow block must be set inside the nozzle. Increase the fluid resistance, reduce the fluid resistance in the boundary area, the two ribs are moderate resistance control.

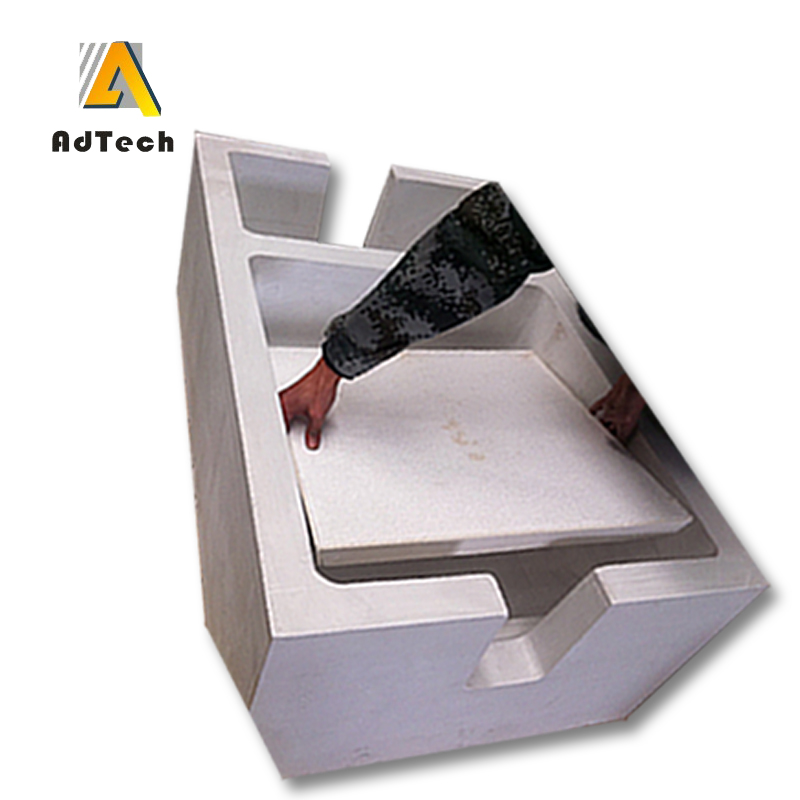

The casting nozzle includes an upper pressure plate and a lower pressure plate which are oppositely arranged, and a plurality of shunt blocks are arranged between the upper pressure plate and the lower pressure plate. When you need to adjust the opening degree, you need to tighten or loosen the threaded connection, because the upper and lower splints are each one-piece structure.

So there are the following disadvantages

1.It is impossible to adjust the asymmetrical shape by using the opening degree.

2.The opening of the nozzle cannot be adjusted differently in different regions.

3. The opening of the casting nozzle cannot be adjusted online.

Therefore, the straightness of the casting nozzle is higher.

The skill of the riser on the riser is high, and it is difficult for the casting and rolling area.

Therefore, it is really necessary to choose a powerful nozzle manufacturer, and we Evans is one of the first choices.

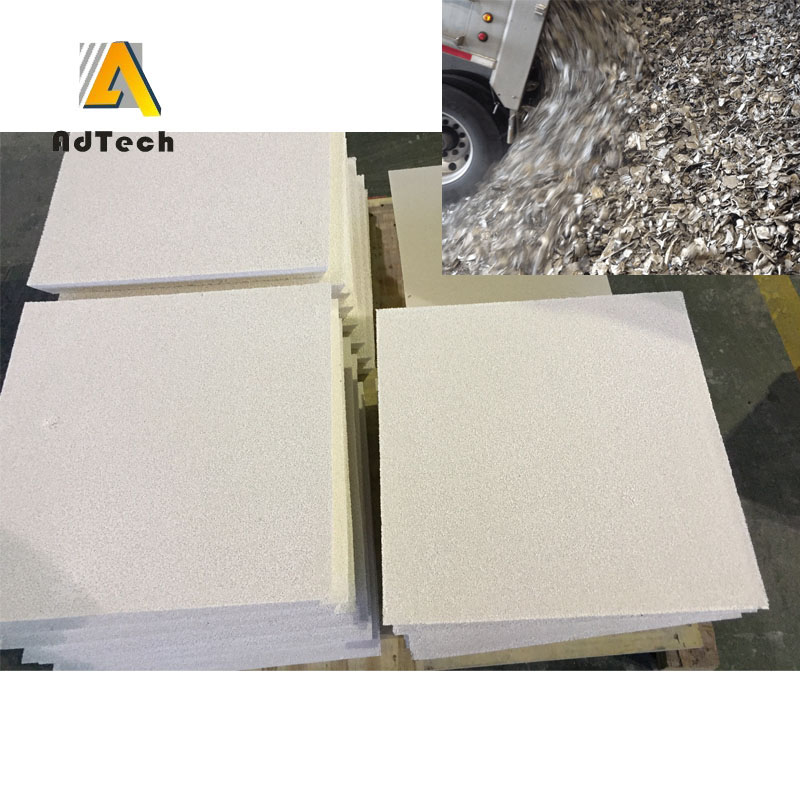

ALuminium Ceramic Fiber Castertip eliminates the fixed split block in the existing cavity of the casting nozzle based on the simulation calculation of convection and temperature fields.

A row of controllable brake blocks is placed in the front box next to the casting nozzle, and a flow control device that synergistically regulates the flow field, temperature field, solute (alloy element) concentration field of the aluminum melt and the quality of the strip is used to improve The quality of the cast and rolled strip billet creates good conditions, with simple equipment, convenient operation, strong functions, safety and reliability, suitable for industrial production and so on.

Sorry, the comment form is closed at this time.