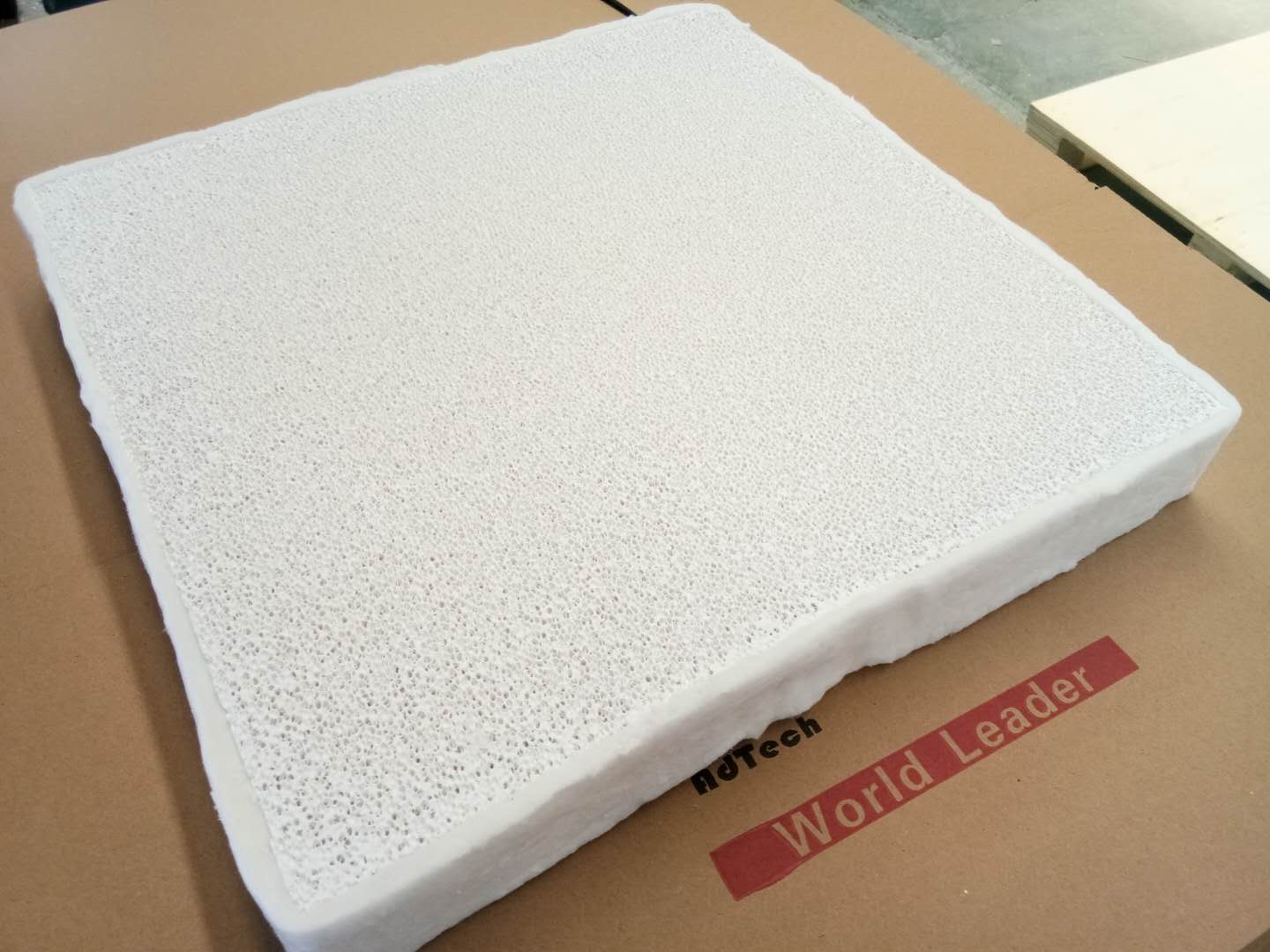

17 11月 30ppi 40ppi Foundry Filter

30ppi 40ppi Foundry Filter is a relatively important filter element in the aluminum casting industry. Used for filtering and purifying aluminum melt, providing high quality guarantee for aluminum alloy

The knowledge of ceramic filter plates is closely related to everyone. I believe everyone knows the ceramic filter plate. Ceramic filter plates are divided into: ceramic filter plates Filter-PZr and ceramic filter plates Filter-PAL. Models are also called ceramic filters, ceramic plates, ceramic plates, filter plates, etc.

Main features of Foundry Filter

1. Filtration accuracy includes fine filtration, microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, with good results.

2. High mechanical strength, anti-caking.

3. High efficiency, high output, beautifully arranged filter mesh, uniform and neat.

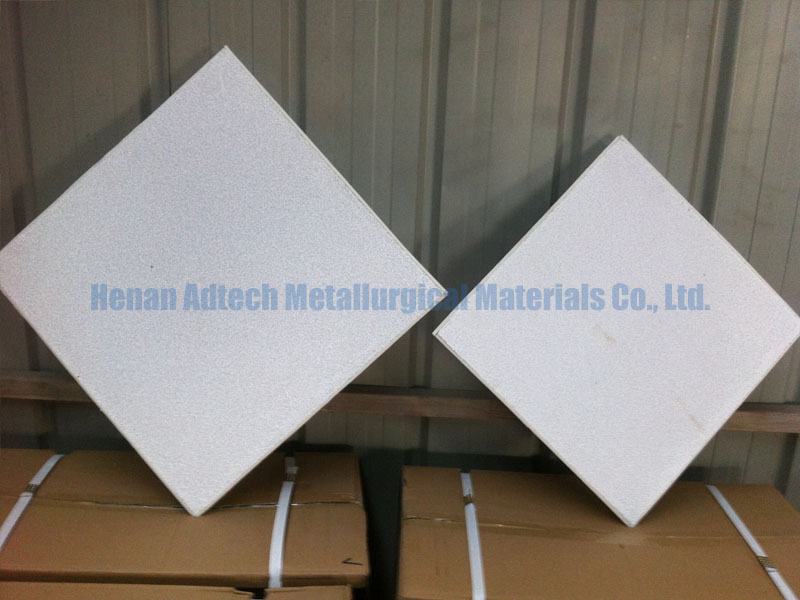

Ceramic foam filter Dimention

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

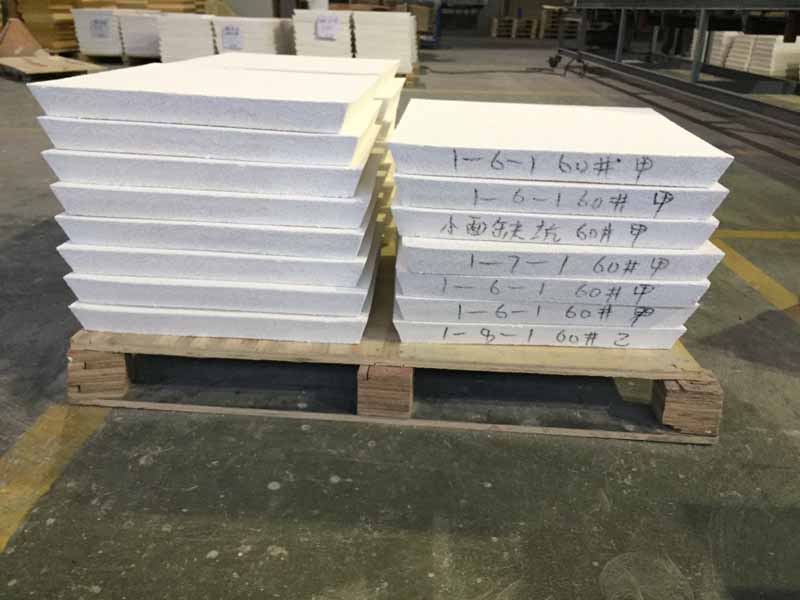

Ceramic foam fitler Pore Size (PPI): 10/20/30/40/50/60

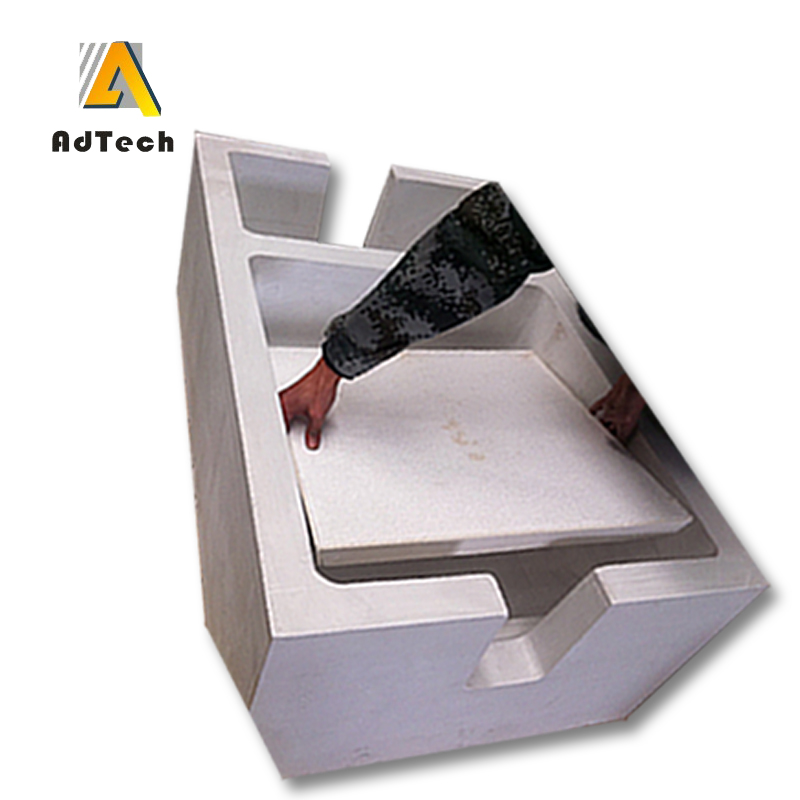

There is an 8mm aluminum silicate liner around the ceramic filter plate to seal the contact part of the filter plate and the filter box to ensure that there is no aluminum liquid bypass.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Therefore, 30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Foam Ceramic Filter is mainly used in the casting process to purify liquid casting alloys and reduce or eliminate various non-metallic inclusions and exhaust problems during castings.

Casting waste caused by casting defects such as non-metallic inclusions accounts for 50%-60% of the total number of waste products.

With the increase of various costs, the damage to the external environment caused by the outflow of excess waste can be predicted, and the inclusion defects not only seriously affect the mechanical properties and casting performance of the casting, but also have a harmful effect on the cutting process and appearance of the casting.

Sorry, the comment form is closed at this time.