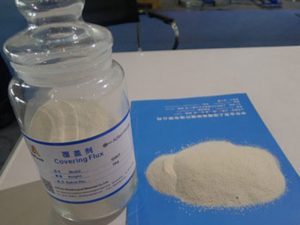

21 9月 What is the covering agent for aluminum

The covering agent also called cover flux, is used for surface covering during the refining and heat preservation of aluminum and aluminum alloys. It can isolate the molten aluminum from the air to reduce the burning loss in the smelting process and the inhalation and oxidation in the heat preservation process. At the same time, it has a cleaning effect on the oily oxides on the surface of the aluminum material entering the molten aluminum, reducing the degree of pollution of the molten aluminum.

Why use cover flux?

Aluminum is a lively metallic element. In the process of electrolysis, smelting, and transfer, molten aluminum or aluminum alloy easily absorbs gas to form slag inclusions, oxide films, pores, looseness, and other defects (mainly hydrogen and oxygen), thereby reducing the purity of molten aluminum or aluminum alloy. Product quality such as product purity and corrosion performance also affect the processing performance of aluminum and aluminum alloys. Therefore, in the smelting process of aluminum and aluminum alloys, a covering agent needs to be used to prevent oxidative burning and inhalation of metal melts, and to improve the purity and product quality of aluminum or aluminum alloys.

At present, there are few researches on covering flux, and there are the following main problems:

1. The covering flux cannot generate protective gas to actively protect the aluminum melt (ie, aluminum liquid or aluminum alloy liquid).

2. Cover fluxes cannot form a very dense protective film on the surface of the aluminum liquid or aluminum alloy liquid, so the protective effect is not good.

3. The water removal of the covering agent is not complete, and the moisture in the covering flux is easy to react with aluminum, resulting in an increase in the gas content in the aluminum liquid.

4. At present, the covering agent generally does not have the ability to remove slag.

Covering agent features:

The low melting point white powder composed of chloride salt and fluoride salt has good fluidity and can be quickly melted to form a coating layer when sprinkled on the surface of molten aluminum.

Dosage of cover flux for aluminum:

Use 0.5-1.0 kg per square meter of the molten aluminum surface.

Instructions:

After the aluminum is melted to form the liquid surface, the covering flux is sprinkled on the surface of the molten aluminum according to the amount, and the surface of the molten aluminum after slag removal should also be covered with this amount.

No Comments