23 8月 What are graphite rings, and the graphite seal ring?

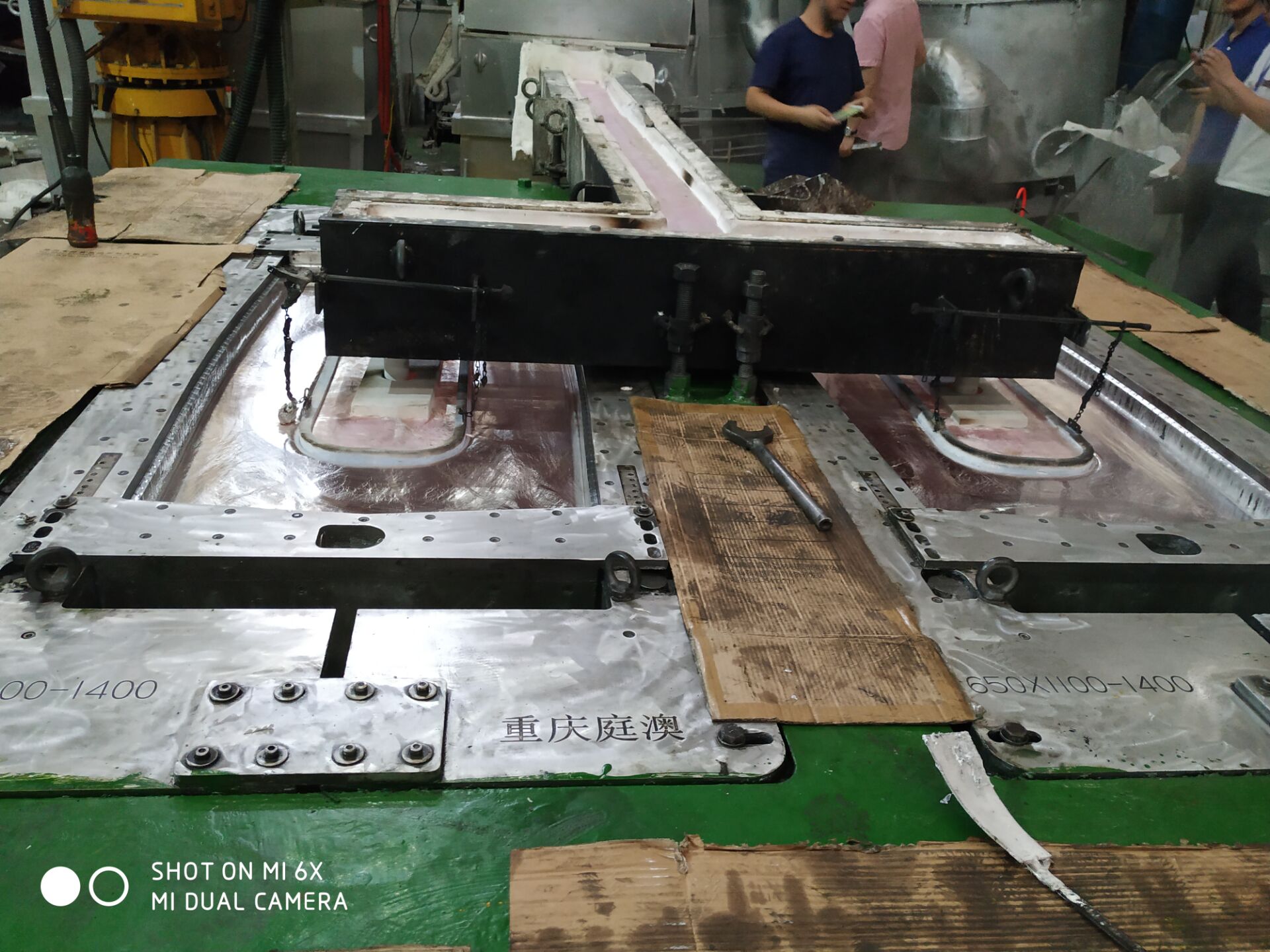

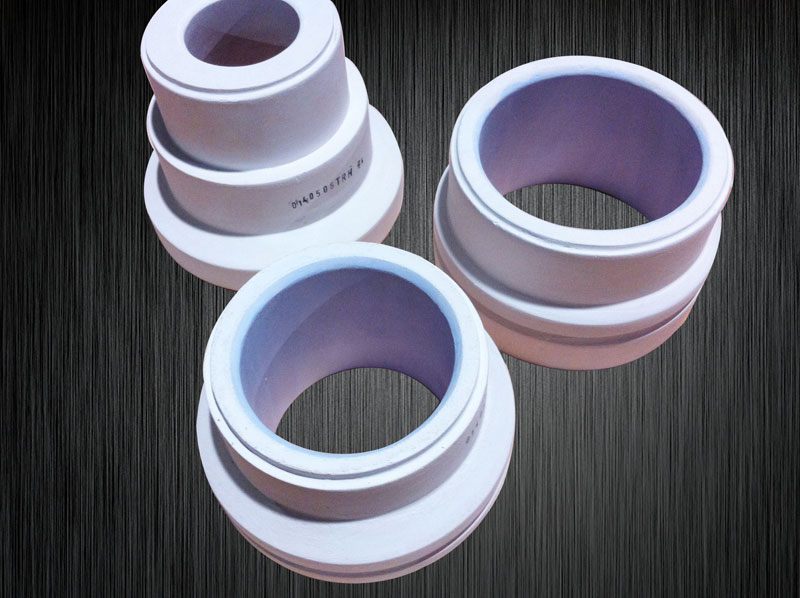

Graphite rings and the graphite seal ring adopt flexible graphite tape or flexible graphite in woven packing and are molded into ring products of different sizes. Suitable for hot water, high temperature, high-pressure steam, heat exchange liquid, nitrogen, organic solvent, hydrocarbon, low-temperature liquid, and other media. Usually, they are used for aluminum bars casting after ceramic foam filters, and the launder system.

For compressors, pumps, valves, chemical instruments, meters, etc. Pressure (Mpa): 25 Temperature (℃): -200~850 Line speed (m/s): 30PH value: 0~14

They are divided into flexible graphite and carbon-graphite rings. Carbon-graphite rings are mainly used in the sealing of mechanical rotating parts. The carbon-graphite ring has the characteristics of high-temperature resistance and corrosion resistance.

The graphite seal ring performance and characteristics:

1. The graphite ring has good self-lubrication

2. The graphite ring has a high rebound coefficient

3. The graphite ring can be cut with a 45° oblique cut according to user needs

Carbon graphite materials for mechanical seals are roughly divided into the following categories:

1. Roasted graphite, in a sense, roasted graphite is divided into hard carbon graphite and soft electrochemical graphite. They are made of petroleum carbon black and soot carbon black mixed with tar, pitch, etc., which are crushed and pressed into green bodies, which are roasted at high temperatures.

In addition to the different components of the material, the main difference between the two is that the latter needs to be graphitized at a high temperature of 2400-2800 ℃.

When graphite is fired, pores (10% to 30% pores) appear due to the volatilization of volatile substances in the binder and the polymerization, decomposition, and carbonization of the binder.

When used as a sealing ring, there will be permeability leakage, and the strength is low, so it needs to be impregnated to fill the gap and strengthen, that is, it becomes an airtight product after impregnation treatment, and the strength is also improved.

However, the temperature and corrosion resistance properties have decreased to varying degrees. There are three main classes of impregnants used: organic resins, inorganics, and metals.

2. Resin-bonded graphite, is to pulverize the sintered graphite, use phenolic resin or epoxy resin as a binder, and then press and sinter it into a product after mixing. The resin in the matrix becomes carbon particles after sintering, so it is gas-impermeable graphite. It has poor thermal conductivity and a large linear expansion coefficient; it is suitable for mass production and has a low cost;

3. It is mainly used for low-load sealing such as automobile cooling water pumps and household appliances.

4. Pyrolytic graphite, domestic pyrolytic graphite is pyrolyzed with propylene and other hydrocarbons at a high temperature so that carbon vapor penetrates into the pores of the carbon-graphite body, which plays a role in blocking pores and forms high-density, few pores, and low permeability.

5. Pure carbon graphite material. Its porosity is less than 1%, its compressive strength is 290MPa, its hardness is 70-75HS, and its linear expansion coefficient is 0.36×10 minus 6 degrees Celsius. Pyrolytic graphite is free of organics and metals and is suitable for high-temperature and strong corrosion conditions. Since it is not suitable for mass production, the cost is high.

No Comments