16 11月 Specialty Custom Molten Aluminium Filter Box

Specialty Custom Molten Aluminium Filter Box

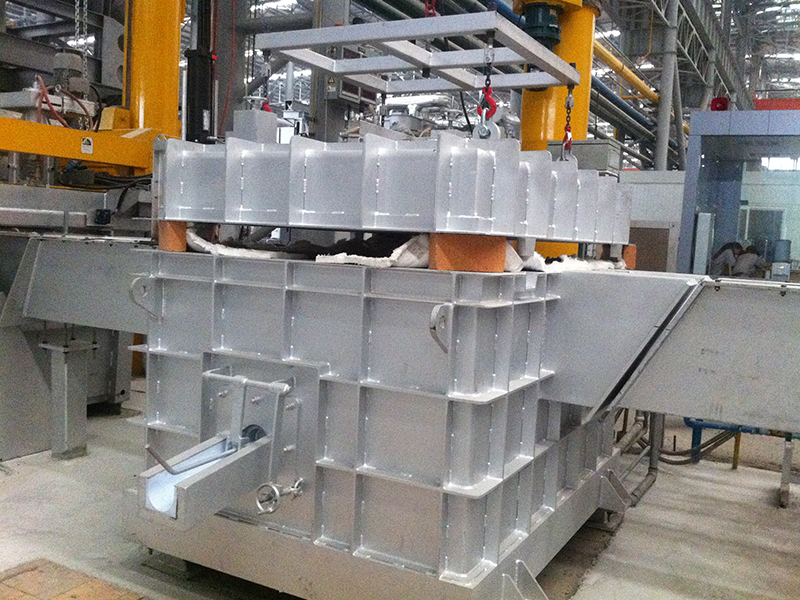

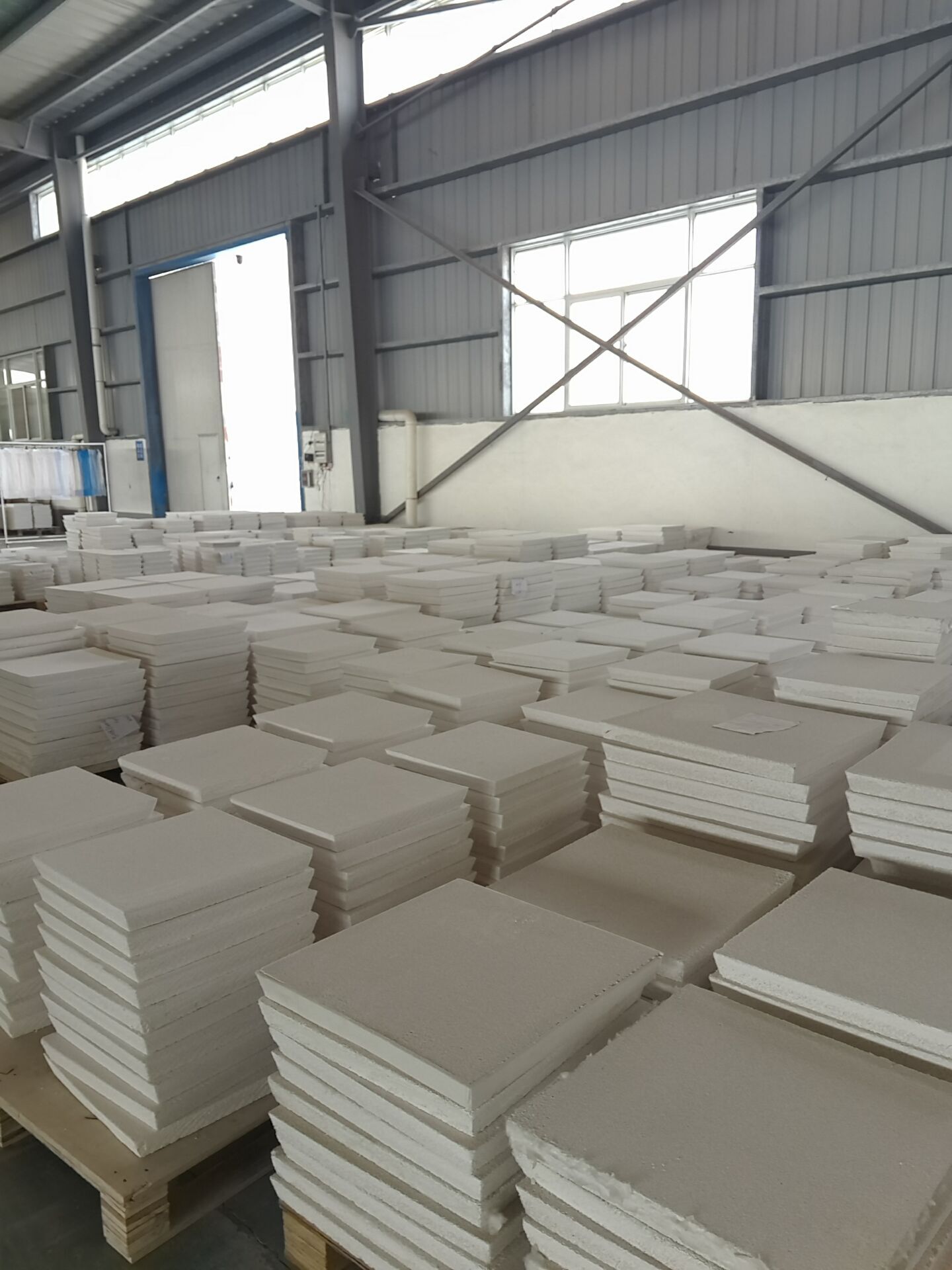

Specialty Custom Molten Aluminium Filter Box is made of a special non-stick aluminum fused silica as the aggregate material, which has good thermal shock resistance, high strength, durability and heat conduction. The coefficient is low.

Specialty Custom Molten Aluminium Filter Box Application

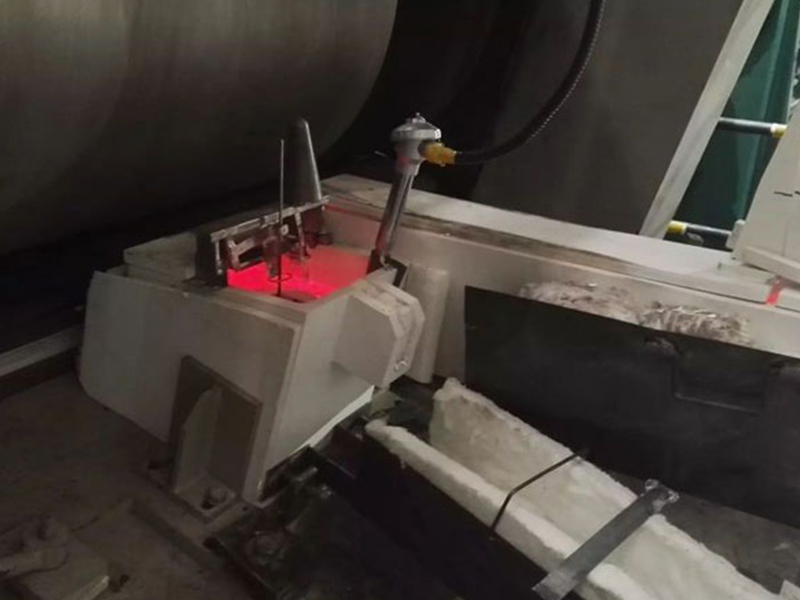

Suitable for casting occasions using ceramic foam filtration.

Specialty Custom Molten Aluminium Filter Box Advantages

1. Can be used directly at room temperature, no need to worry about thermal shock.

2. No thermal expansion, low thermal conductivity.

3. Can float in aluminum, reducing the possibility of refractory inclusions.

Molten Aluminium Removal Technology

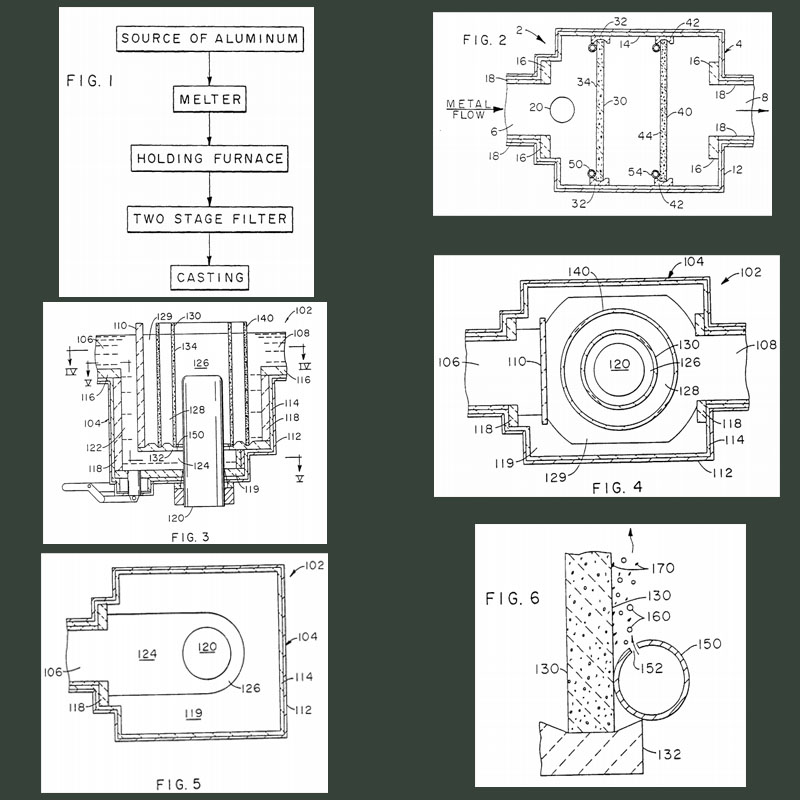

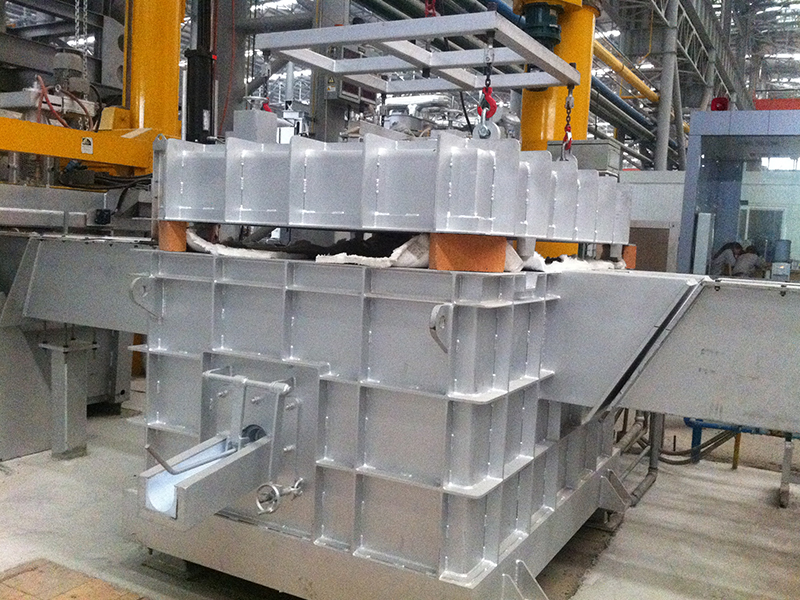

The existing aluminum water removal filter box production line on the market, in the remelting aluminum ingot smelting process, mostly from the melting furnace through the flow tank directly into the casting package, or in the flow tank between the casting package Filter box, but this technology has defects. In the casting process, all the aluminum liquid must be discharged due to temporary parking. Otherwise, the aluminum filter will be solidified in the filter plate in the filter box, which will cause the filter plate to be scrapped. The new filter plate causes waste of working hours and increases production costs.

In response to this process defect, my engineering and technical personnel, after years of process improvement and practice.

Specialty Custom Molten Aluminium Filter Box is to protect the filter plate by providing a partition dam plate in the filter device. At the same time, according to the buoyancy principle in physics, it also plays a purifying role. This technology is used in conjunction with the aluminum liquid purification device applied by our company. The purpose is to achieve the final purification of aluminum liquid through the combination of two sets of devices to realize the aluminum wire rod. The subsequent process can draw fine wires of 1.0 mm or less.

No Comments