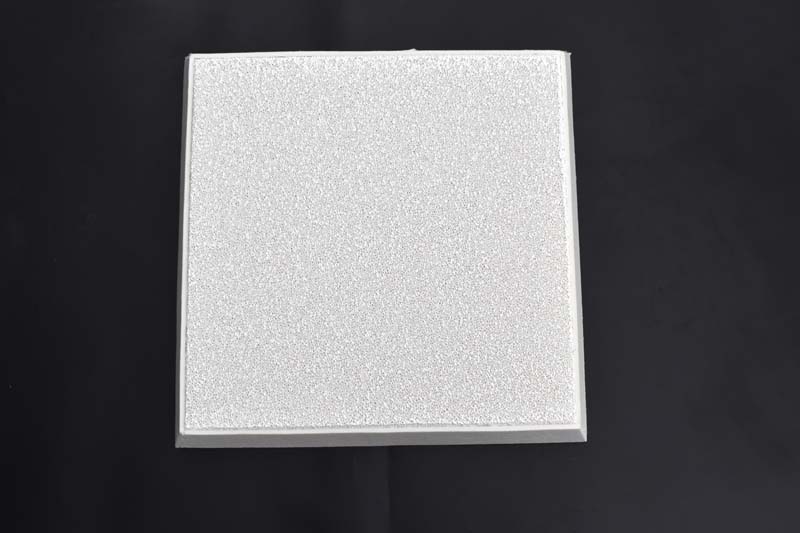

01 7月 Korean Aluminium Ceramic Foam Filter

Korean Aluminium Ceramic Foam Filter is used to remove the inclusions generated between the refining system and the hot top casting platform. During the metal solidification process, the ability of the ceramic foam filter to capture these inclusions is critical to keeping the aluminum ingot clean. This...