17 4月 Reduce casting loss during aluminum Aluminum Foundry

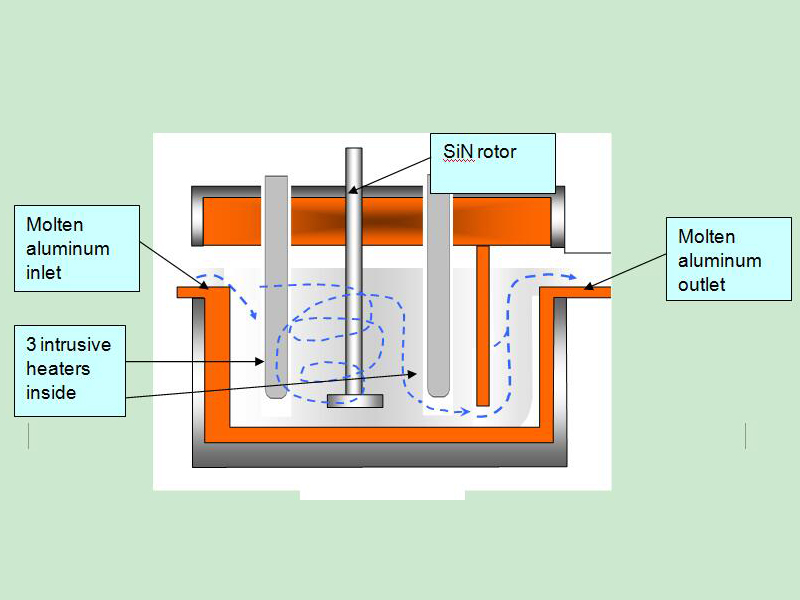

Reduce casting loss during aluminum Aluminum Foundry Aluminum Foundry Casting converts liquid aluminum into finished products and semi-finished products of aluminum ingots, bars or other shapes through processes such as batching, stirring, standing, refining and slag. Aluminum and aluminum alloys will have different degrees of loss...