25 3月 Flux Removes Hydrogen In Liquid Aluminium

Flux Removes Hydrogen In Liquid Aluminium which is a key technology to ensure the quality of aluminum alloy materials. Reducing the hydrogen content in the aluminum alloy liquid is one of the main purposes of aluminum alloy purification.

The Removes Hydrogen In Liquid Aluminium technology can be divided into two categories: adsorption purification and non-adsorption purification according to the principle of action. The adsorption purification is by adding Refine Flux to the aluminum alloy liquid, so that the Refine Flux and the aluminum alloy liquid are in contact with the aluminum alloy. Chemical, physical or mechanical action to achieve the purpose of hydrogen removal.

Non-adsorption purification is to change the liquid-gas equilibrium state of aluminum alloy through certain physical effects such as vacuum, ultrasonic, etc., so as to achieve the purpose of separating the gas from the aluminum alloy liquid.

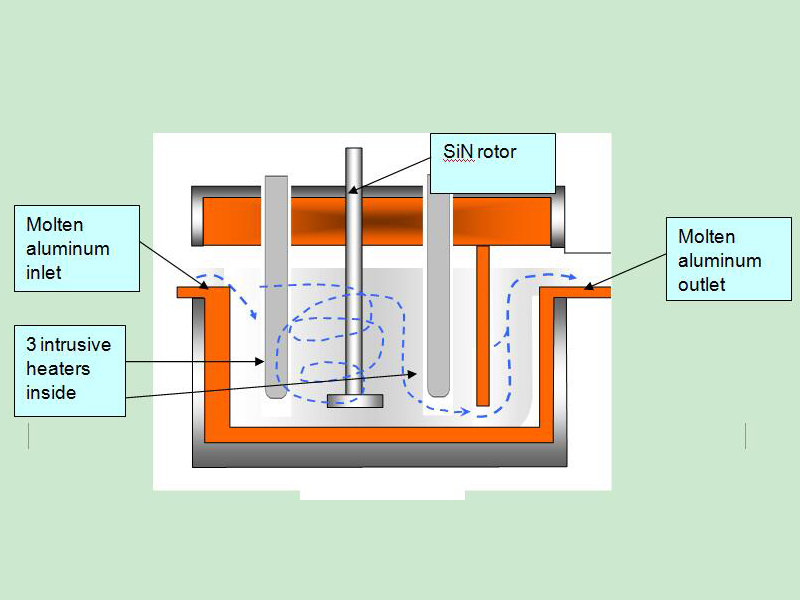

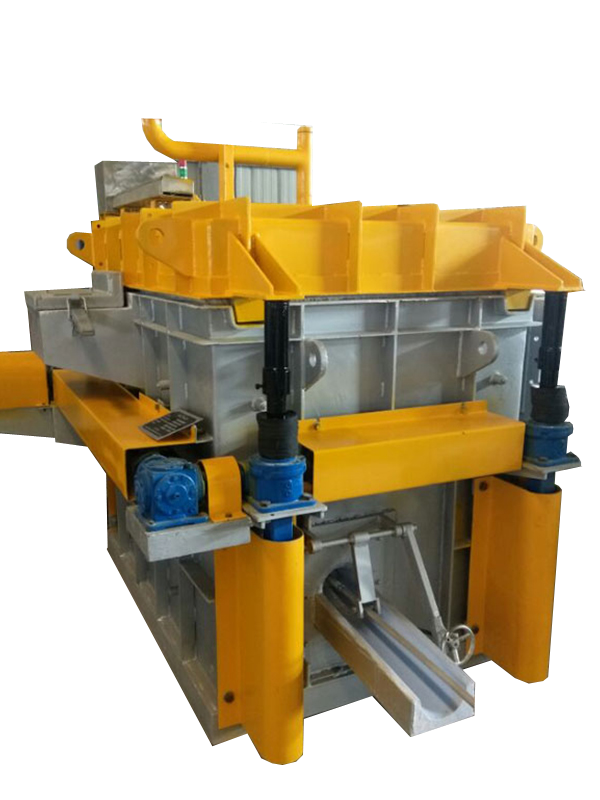

When the Degassing Unit is used to adsorb and purify the aluminum alloy liquid for hydrogen removal, since the efficiency of hydrogen removal can be improved by improving the kinetic conditions of hydrogen removal, the operation is convenient and the pollution is less.

According to the gas introduction method, it can be divided into single pipe method, multi-hole blow head method, fixed nozzle method and rotary spray method. The Degassing Unit uses a rotating rotor to remove hydrogen.

In the field of aluminum processing, the purification of aluminum alloy melt, especially the control of gas (hydrogen) and inclusions in the melt, is more difficult.

The fine oxide inclusions and gas (hydrogen) form a mutual parasitic relationship in the aluminum alloy melt.

Since the overall density is roughly equivalent to that of aluminum melt, it is difficult to overflow the liquid surface before the alloy solidifies.

After the solidification is completed, the melt is retained in the melt to form casting defects such as inclusions, shrinkage holes or pores. These defects are also difficult to eliminate in a series of subsequent processing procedures (such as rolling, extrusion, heat treatment, etc.), resulting in mechanical properties. Deterioration, especially plasticity and fatigue properties.

Flux Removes Hydrogen In Liquid Aluminium, this method can optimize the quality of aluminum alloy. Improving the purification efficiency and purification level of aluminum alloy melt is the key to producing high-quality aluminum alloy castings.

At present, refining fluxes are commonly used, and NaCl and KCl with eutectic components are commonly used as main salt systems.

Properly add other auxiliary fluxes to improve the efficiency of the refining flux to capture non-metal oxide inclusions and degassing.

Cryolite can dissolve alumina and form a mixed solution with low surface tension, but cryolite-alumina melt dissolved in a small amount of aluminum will turn into a colloidal solution, which will affect its fluidity and spreadability.

Flux Aluminium is beneficial to remove the dispersed fine inclusions and free hydrogen in the aluminum alloy melt. On the one hand, it improves the wettability of molten aluminum-alumina inclusions, and on the other hand, it is easy to form aluminum melt regions rich in rare earths.

No Comments