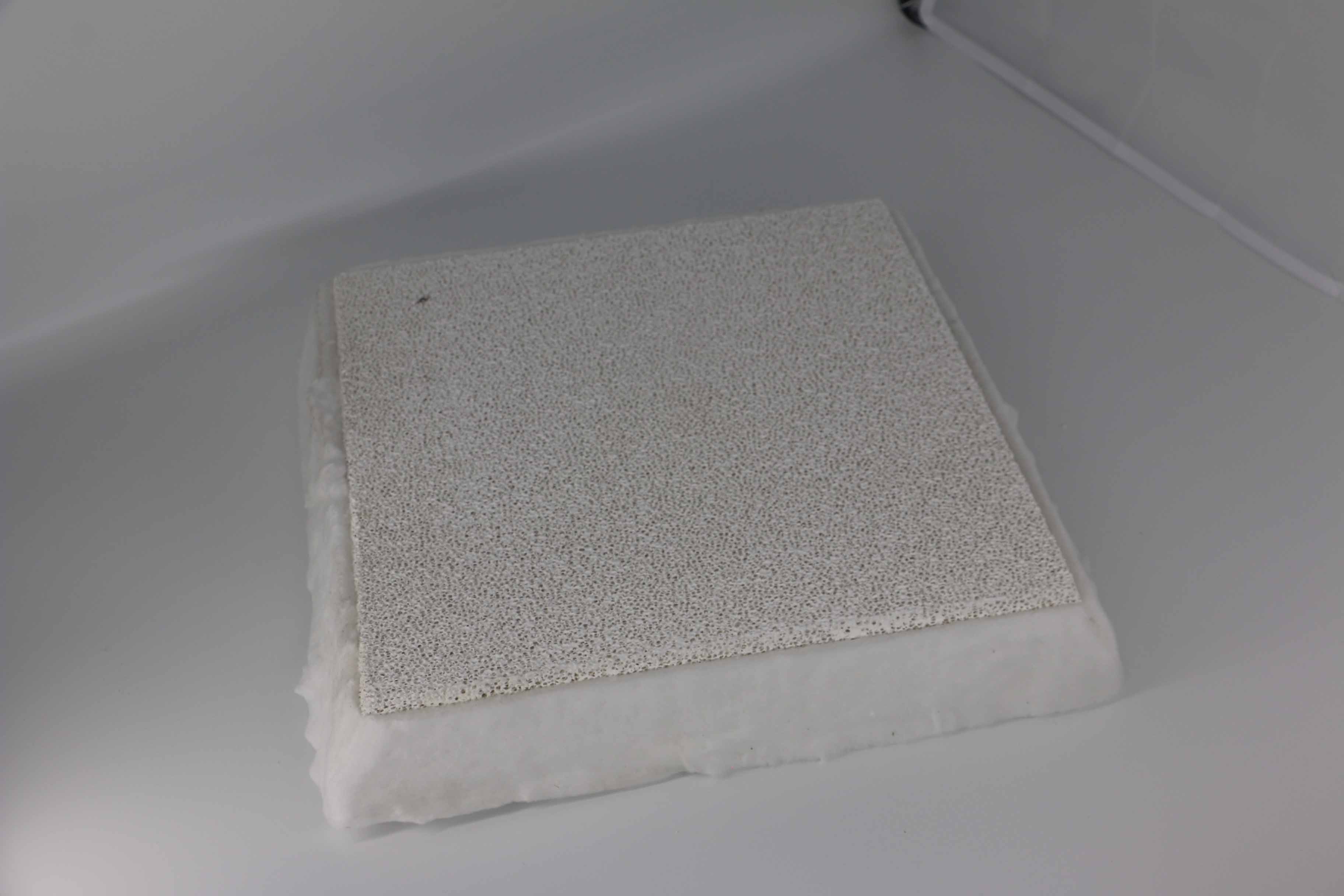

04 8月 Buy Ceramic Foam Filters

Buy Ceramic Foam Filters from China Adtech, you will know its basic principles and be able to use it better. The usual manufacturing method of foam ceramic filter plate is to invade the polyurethane sponge into the ceramic slurry, extrude the excess part, dry, and finally...