12 10月 Foundry Double Rotor Deaerator

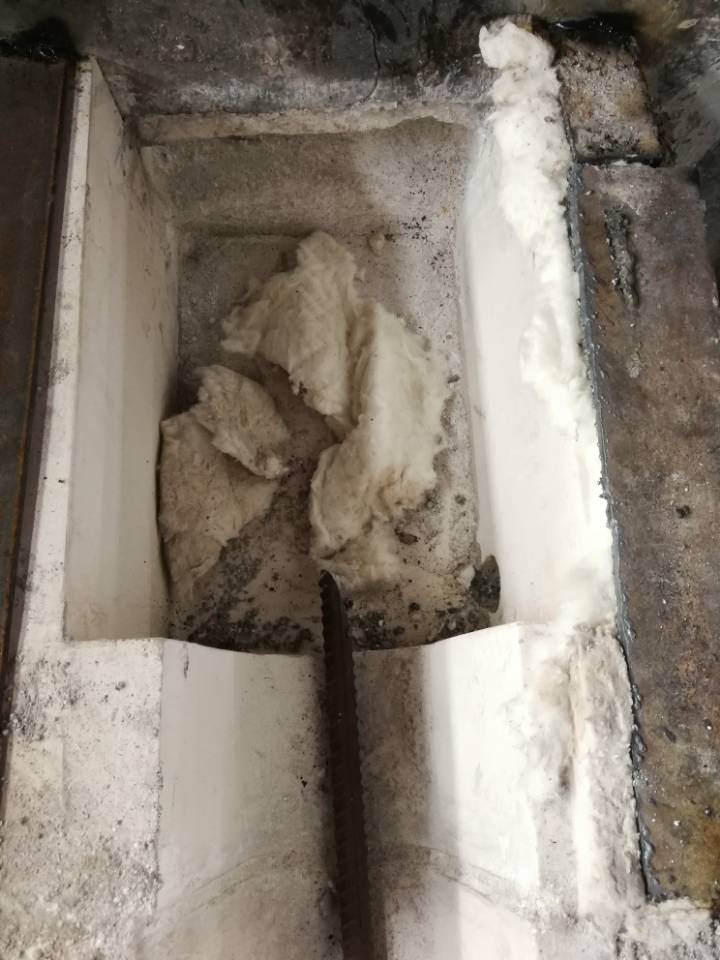

Foundry Double Rotor Deaerator The Double Rotor Deaerator is designed for on-line degassing of aluminum fluids with high flow rates, high gas content and high inclusions. It has two independently controllable steering rotors with opposite rotations to provide more powerful agitation. Gas capacity, the equipment is...