14 12月 Feeding Tip

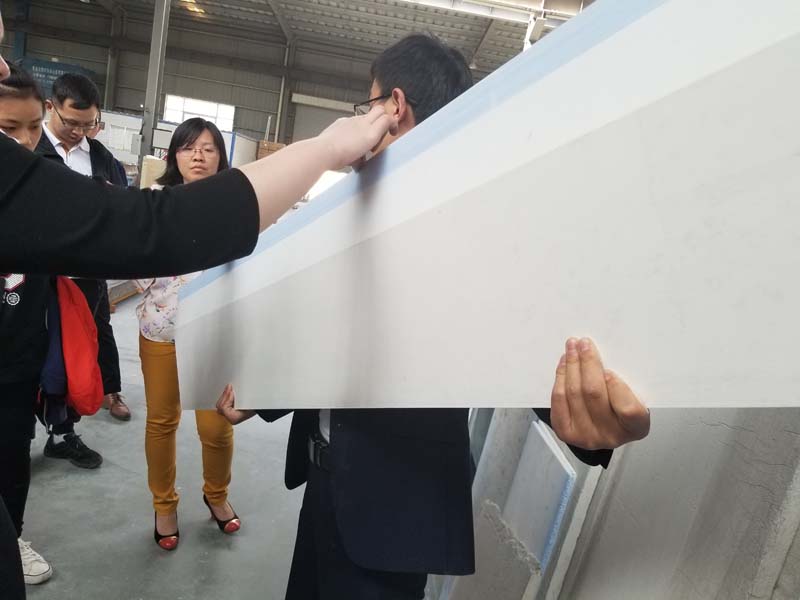

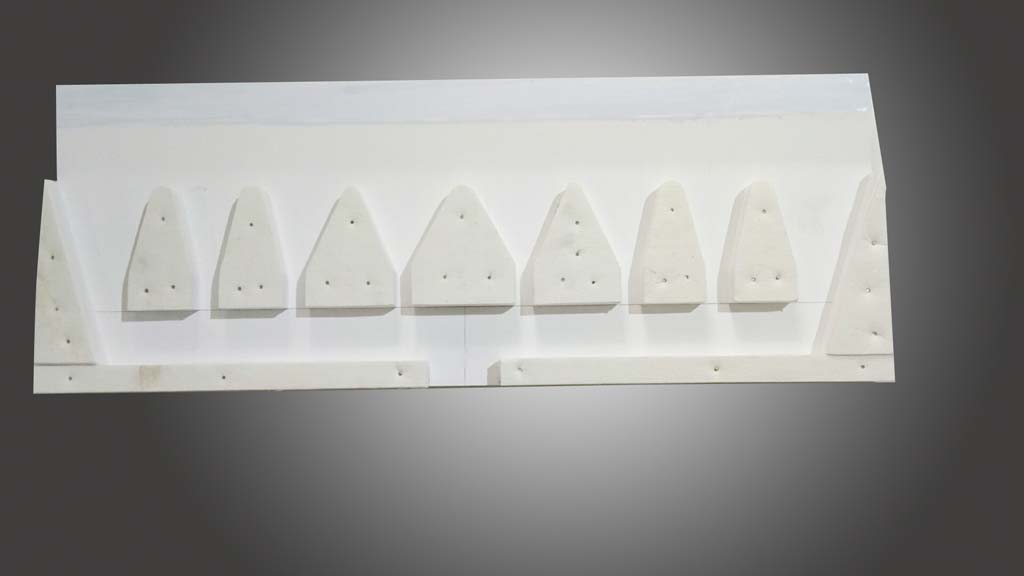

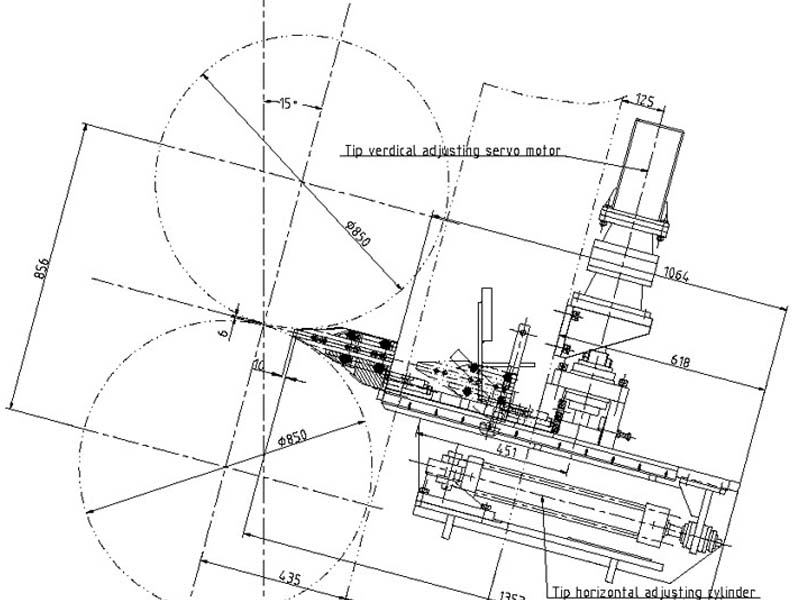

Feeding Tip is a key component of Aluminum sheet Casting. Its quality directly affects the quality of the strip and the yield of production. The aluminum silicate casting nozzle material can be divided into various types according to the performance and needs of different casting...