30 11月 Aluminum Tip Cavity

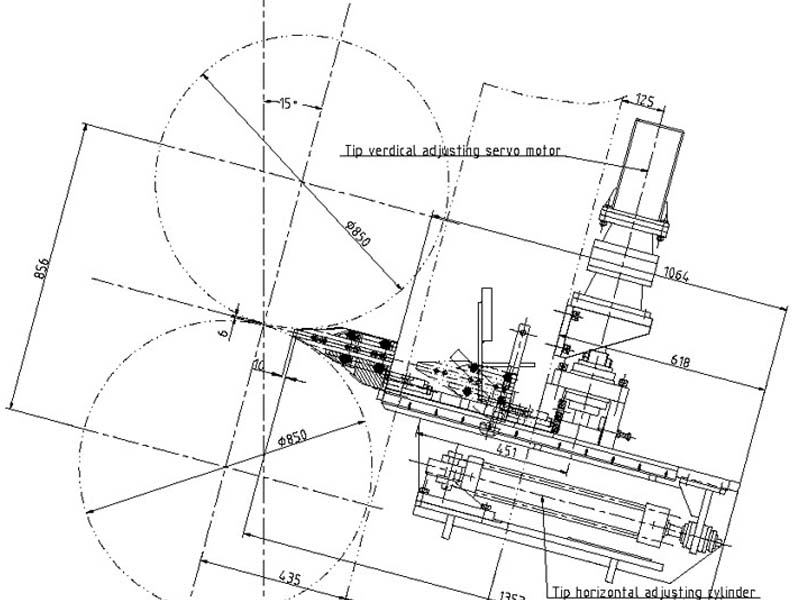

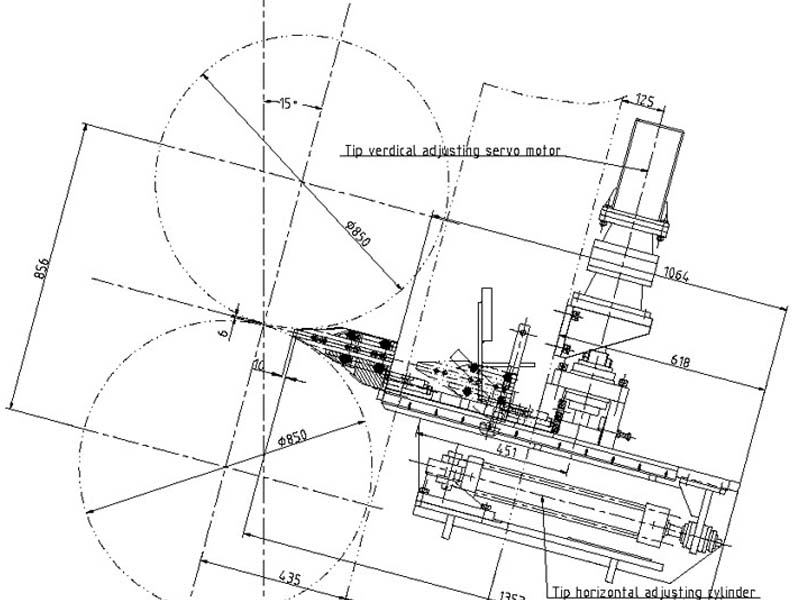

Aluminum Tip Cavity is installed on the entrance side of the casting and rolling mill for casting strip. The hydraulic cylinder drives the casting nozzle platform to slide on the sliding seat, pushing the casting nozzle and its auxiliary parts to a certain safe distance from the roll gap of the casting mill, and then the casting nozzle horizontal and vertical adjustment device driven by the servo motor adjusts the casting nozzle to For the target position, the servo motor can individually adjust each side of the casting nozzle online as required.

Castertip installation process

A. Fix the casting nozzle in the nozzle clamp of the steel structure, and then fix the nozzle clamp on the nozzle platform. The in/out and up/down position adjustment of the nozzle platform can be carried out at the same time or separately.

B. When the vertical plate swings the roll gap, first adjust the horizontal adjustment screw jack of the casting nozzle platform to the maximum stroke, and then the oil cylinder drives the casting nozzle platform to the direction of the roll gap at a faster speed, when the front end of the casting nozzle is 120mm from the center line of the roll At this time, the baffle plate of the casting nozzle platform is pressed against the top plate of the screw elevator, and then the servo motor drives the casting nozzle platform to slowly approach the roll to adjust the casting nozzle to the target position.

C. When the casting-rolling mill is stopped to change rolls, the oil cylinder drives the casting nozzle platform back to the rear limit position, and the detection signal of the rear limit switch is used as the condition for roll change.

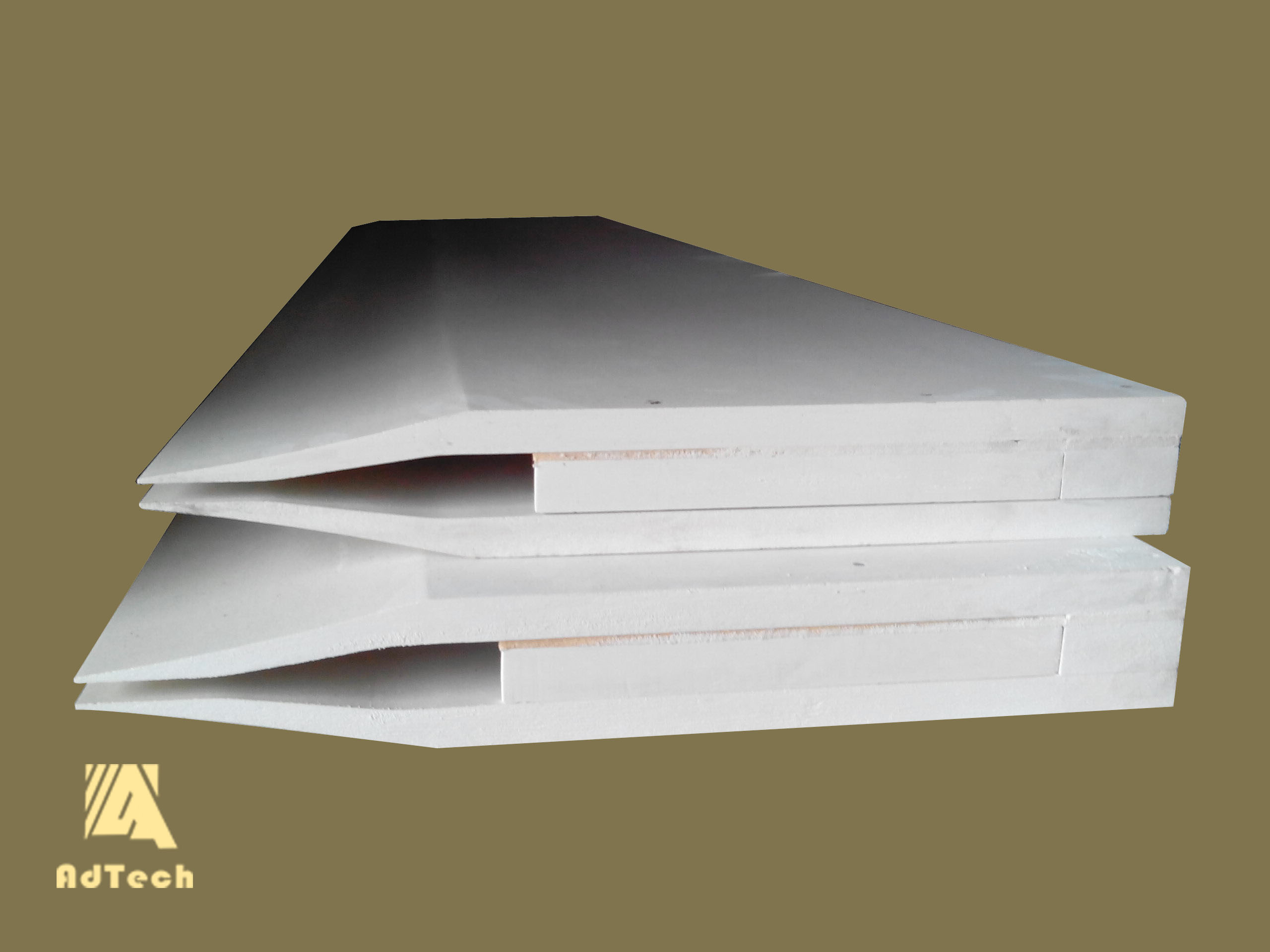

Soft ears & hard ears product use:

Soft ears & hard ears are assembled with nozzle plate, used for crystal forming and size control of aluminum sheet, strip and foil blanks in the casting and rolling production line.

The soft ears are made of high-aluminum fiber cardboard paste and composite molding, and the hard ears are made of high-purity fiber vacuum suction filtration. Both are baked in a kiln and processed by precision equipment.

AdTech (Ivans) soft ears & hard ears are assembled with the nozzle plate. They are mainly used to adjust the internal flow blocking and control the aluminum alloy forming size. The uniformity of the edges without burrs can effectively protect the casting in the rolling production. The internal structure of the rolled coil is stable.

Headbox product advantages

The assembled flow controller has the function of automatic and stable flow control, replacing the traditional manual flow control, effectively reducing labor costs and improving the stability of molten metal flow.

Adopting high-silicon molten material molding technology with a density of 1.0-1.4g. cm3, good heat preservation performance, smooth surface, good non-wetting property, multiple use, solving the traditional disposable flow control box replacement, effectively saving traditional materials 3-4 times the cost.

Aluminum Tip Cavity is a comprehensive technology that integrates solidification and deformation.

The nozzle structure and assembly are one of the most critical technologies for double-roll continuous casting and rolling. It is the component that directly distributes the molten metal to the roll gap of the casting roll. Therefore, the distribution of the flow field and temperature field in the nozzle cavity directly affects the plate. shape.

In particular, the exit velocity of the high-temperature shallow aluminum melt in the nozzle cavity and the uniformity of the exit temperature distribution determine whether the casting and rolling process can proceed smoothly and whether high-quality cast slabs can be obtained.

Therefore, it is of great practical significance to study the complex three-dimensional flow field and temperature field distribution of high-temperature shallow aluminum melt in a cavity with large width to thickness ratio and variable cross-section, and to analyze the influence of different parameters on the outlet velocity and temperature distribution of high-temperature shallow aluminum melt.

Sorry, the comment form is closed at this time.