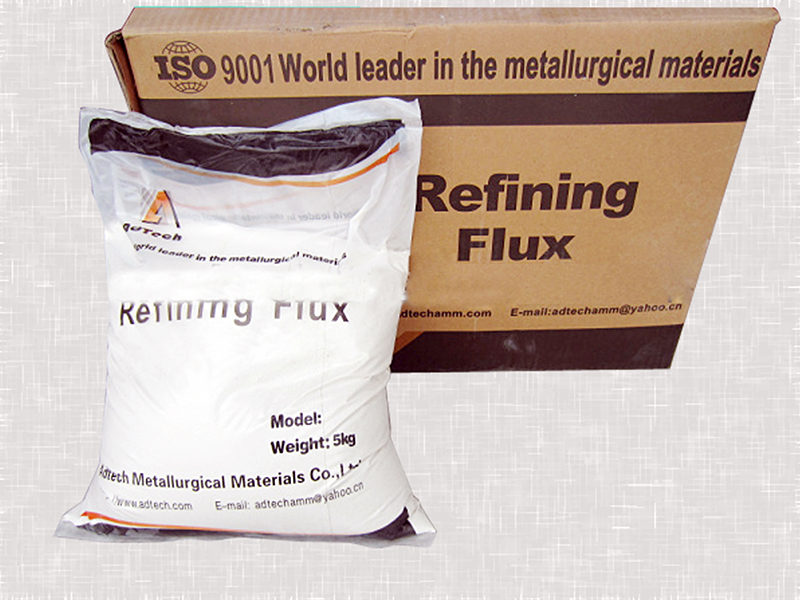

12 6月 Aluminium Refine Agent

Aluminium Refine Agent removes gases and solid non-metallic inclusions from the melt through physical, chemical or physicochemical interactions in aluminum and aluminum alloy melts.

Due to its small density, high specific strength, good electrical conductivity, beautiful outer tube and moderate price, aluminum and its alloys are not only used in aviation, aerospace, ships and other military industries, but also in building materials, home appliances, power and telecommunications lines. Cables and other civil industries have also been widely used.

During the production of aluminum alloys, hydrogen atoms in the solution will spontaneously form hydrogen, and hydrogen and inclusions form bubbles during the solidification of the aluminum alloy solution, causing defects in the aluminum alloy components. Due to the presence of impurities and gases in the aluminum alloy solution, it is essential to use the Aluminium Refine Agent. It is very important to improve the metallurgical quality of aluminum alloys through refining. At present, the refining agents used generally have a problem of poor refining results.

Causes of inclusions in 7075 aluminum plate and 5083 super flat aluminum plate

1. Caused by raw materials. The aluminum ingots, intermediate alloys, and scraps in the raw materials contain impurities such as oil stains and moisture. Easy to form oxides and refractory inclusions.

Additives such as covering agent, slagging agent, Aluminium Refine Agent, refiner, etc., can easily form potassium, sodium, chlorine, A13TI, TIB2 and other mixed graphite emulsion and combustion medium used in thermal spraying, refining gas, melting and flow tank heating The combustion medium used, such as heavy oil, liquefied gas, etc., can easily form carbon, aluminum nitride, chlorine, sulfur and other inclusions.

2. The furnace, supply system, tools, etc. are not clean, the fine dust of the casting nozzle, the peeling of the casting nozzle, and the slag are susceptible to the formation of calcium, silicon, alumina and other inclusions.

3. Improper process and operation, such as unclean slag slag, improper stirring, excessively high melting temperature, and excessively long melting temperature, are likely to form oxidation inclusions.

4. Degassing and filtering effects are not good.

Aluminum ingot casting process

Aluminium-slag slag-inspection weight-ingredients-loading furnace-scouring-casting-aluminum ingot for remelting-finished product inspection-finished product inspection-aluminum storage-slag slag-inspection weight-ingredients-furnace-scouring-casting —Alloy ingot—cast alloy ingot—finished product inspection—finished product inspection—in storage two, primary aluminum purification

The aluminum liquid drawn from the electrolytic cell contains various impurities, so it needs to be purified before casting.

The industry mainly adopts purification methods such as clarification, flux, gas, etc., and some try directional solidification and filtration methods for purification.

Sorry, the comment form is closed at this time.