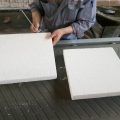

22 12月 Alumina Casting Filter

Alumina Casting Filter can effectively remove and absorb various impurities in molten aluminum, improve surface quality, product performance and microstructure effectiveness. Mainly used for precision casting of aluminum alloy.

AdTech Casting Filter is sold all over the world for the purification of molten aluminum. AdTech focuses on the aluminum alloy casting industry, providing solutions for Molten Aluminum Filtering System, hot top casting system, castertip, etc.

Our Casting Filter can clean aluminum and is used for aluminum billet casting, foil casting, slab casting, etc.

Casting Filter filtration efficiency

The filtration efficiency of the Casting Filter depends on the pore size of the filter plate, the size and type of inclusions (density, wetting characteristics) and the speed at which molten metal passes through the Casting Filter.

The Casting Filter is surrounded and sealed by an expanded gasket. The expanded gasket expands 200% above 450°C to prevent molten aluminum from floating and leaking through the contact surface.

Casting Filter filters through the principle of adsorption, which can effectively remove large impurities in the aluminum liquid and effectively adsorb micron-sized impurities. The filtration efficiency of the same ppi is high.

Gasket of Casting Filter

A gasket is applied around the Casting Filter to act on the contact surface of the Casting Filter and Filtering Housing to prevent liquid aluminum from leaking through the contact surface.

Our Casting Filter is made of three different types of gaskets, including fiber paper seal; fiber cotton seal; expandable gasket seal.

Ceramic foam filters are basically divided into 6 pore sizes: 10PPI, 15PPI, 20PPI, 25PPI,

30PPI, and 40PPI. The larger the number, the smaller the aperture. But in actual practice, the

four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

Aperture selection

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p

How to choose Alumina Casting Filter for various aluminum castings?

1. Aluminum alloy bar selection: 10-30ppi

2. Long-term casting options: 30-50ppi

3. High-quality aluminum profile or plate selection: 40 or 50ppi

4. Double zero wave continuous casting and rolling options:> 50ppi

5. Other specifications can be customized according to your requirements

Sorry, the comment form is closed at this time.