30 10月 Italy Aluminum Ceramic Filtration

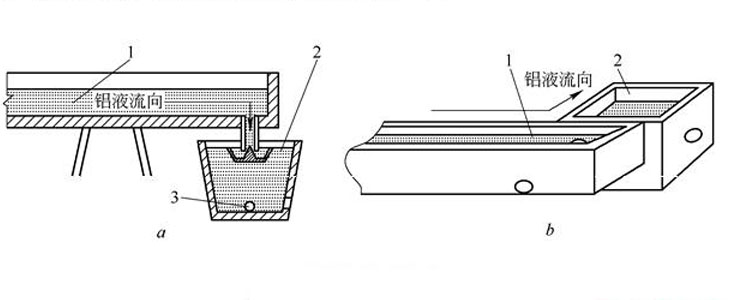

Italy Aluminum Ceramic Filtration is a three-dimensional connected network structure with high porosity, large slag collecting surface area, large filtering internal surface area, small flow resistance, and good filtering effect. Ceramic foam filter Dimention 660x660x50(26") 584x584x50(23") 508x508x50(20") 432x432x50(17") 381x381x50(15") 305x305x50(12") 228x228x50(9") 178x178x50(7") Ceramic foam fitler Pore Size (PPI): 10/20/30/40/50/60 Italy Aluminum Ceramic Filtration is mainly used...